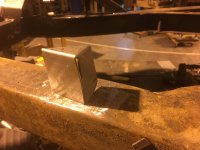

Thank you Graham, the pictures are helpful. I had an idea of how it is supposed to go but wanted to see other cars to be sure. Tonight I removed the driver side spring tower. So lets see what is behind door #1. When I saw the patch under the fulcrum pin mount I had a good idea what was behind door #1 and it was no surprise. The person that did the repair did the exact same damage to the inner channel, they just did a better job of covering it up this time. I will be doing almost the same repair as I did to the passenger side. The top of the frame will be replaced, the inner channel flange will be replaced, The inner channel of the spring tower will be replaced, new fulcrum support brackets , repair the bump stop water box, then I get to put it all back in place. When I bought the car I did not know a good frame from a not so good frame and I trusted the man , he seemed honest , he pointed out the obvious but told me the frame was good. I don't know if he really had the knowledge to say it was good or not. Now I know and hope this will help others to know what to look for. I knew I had a lot to repair but I did not know it would be from self inflicted wounds. I will tackle this bump in the road and hope to have the frame done by the end of the month. I have already done this so this time should be a little easier. Frank

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.