OP

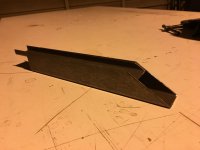

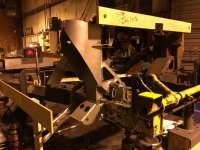

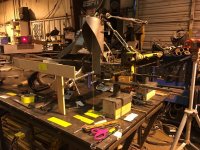

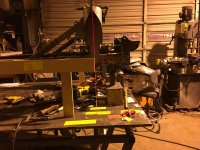

Offline

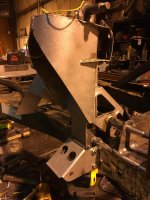

Hi John, I have 2 lasers that I will be using to setup the final alignment, tack welding, and final check before and after welding. I had forgotten about using a water level to check the floor. I have a very accurate 6 foot level I was planning on setting pads to measure off of to level and check the frame for twist. The water level will be a great way to make sure all the pads are shimmed to a perfect measuring surface. Last night I started removing the extra plates to get a feel for how hard this will be. Pretty easy to remove the plates so I am not worried about this repair. The top 18 inches of the top of the passenger frame rail will have to be replaced. Whoever did the welding built up areas with weld metal, in some places it is a pad 1/4 inch thick. They had no idea what they were doing. Thank you for the suggestion, that is great to have ideas that make the repair easier and better. Frank

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.