Tinster said:

1. Is this cleaning something a non-mechanic can accomplish?

I don't think you'll have any trouble at all, Dale. And I would definitely recommend it if you have a rocker that isn't getting oil. Basically remove the shaft from the engine (complete with rockers), then drive or pull out the pins that hold it together (not sure offhand if your TR250 motor will have cotter pins or solid pins) and the locking screw in one of the pedestals. At that point you should be able to clean out the inside of the shaft; but I would also remove all the rockers (which means removing the pedestals as well) so they can be cleaned and inspected as well.

Keep everything in order and put it back the way it came apart; pretty easy. I'd call it two wrenches. A drop of blue Loctite on the locking screw is a good idea, IMO.

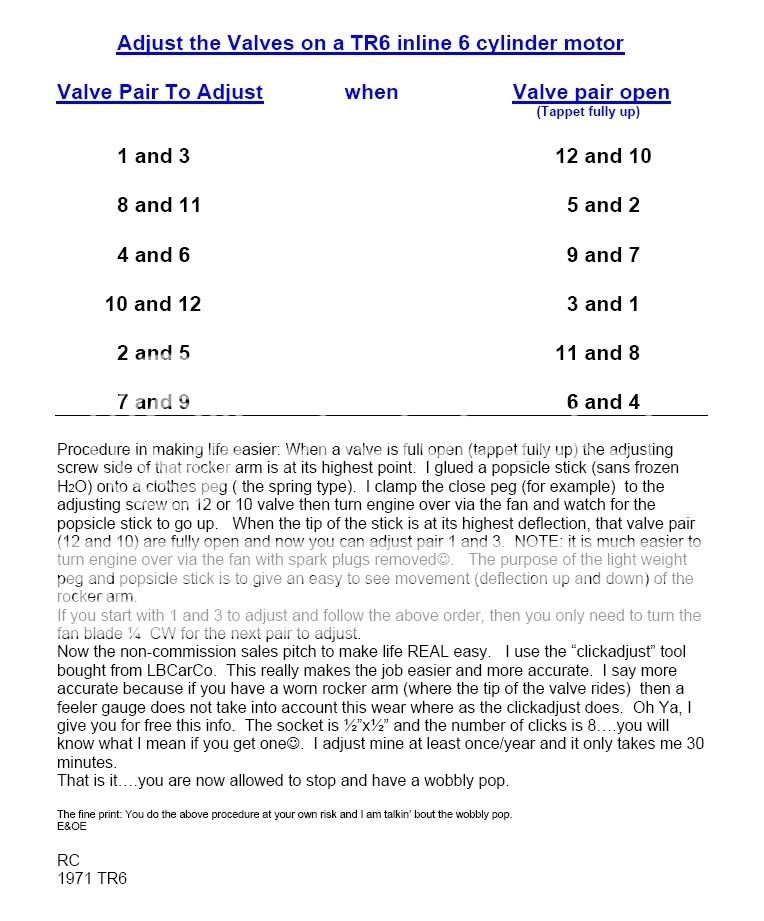

<div class="ubbcode-block"><div class="ubbcode-header">Quote:]2. What is the Rule of Nine? for valve adjustments?[/QUOTE] Well, first of all, for a 6-cylinder Triumph, it's the "Rule of 13". "Rule of 9" is for a 4 cylinder.

Basically it states that, if you number the valves in order from 1 at the front to 12 at the rear, then the number of the valve that is fully open and the number of the valve you can set now always add up to 13. IOW, if valve #1 is fully open, you can set valve #12. If valve #6 is fully open, you can set valve #7. And so on.

Personally, I prefer a different rule; which lacks a catchy name but I find easier (and it works on any 4-cycle engine with an even number of cylinders). Just turn the engine until both valves for a cylinder are moving at the same time, then set both valves on the cylinder that is opposite in the firing order. You can even use the distributor cap to give you the opposite cylinder, just follow the wire for the cylinder with both valves moving back to the dizzy cap, then skip directly across the cap and follow that wire to the cylinder you should be working on.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.