Offline

Hi folks,

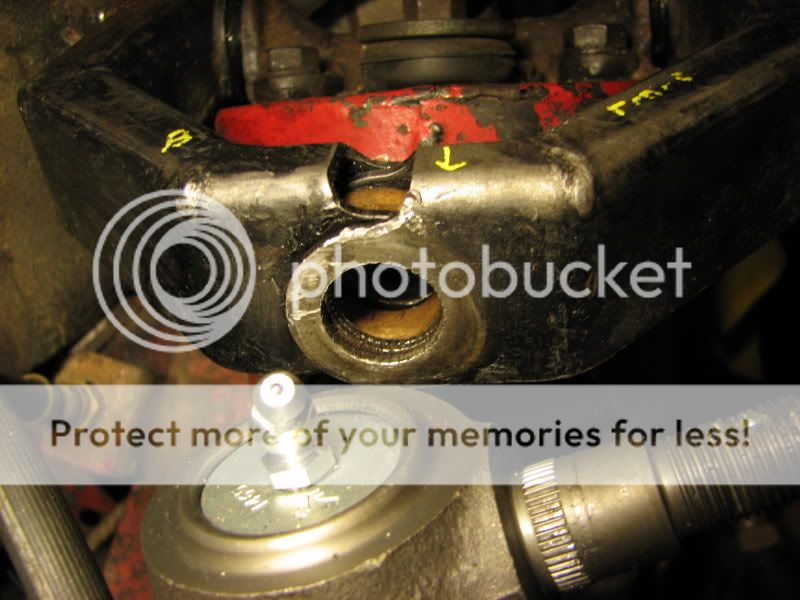

Look what happened to the bolt from the ball joint splinter. Ha!

It's the bolt on the bottom. Then I used an unmarked bolt (colored like a grade 8). That broke as well. Then an old grade 5 - even that bent a little until that pesky ball joint popped. (That's not the original long bolt either - that stripped out when I done the tie rods)

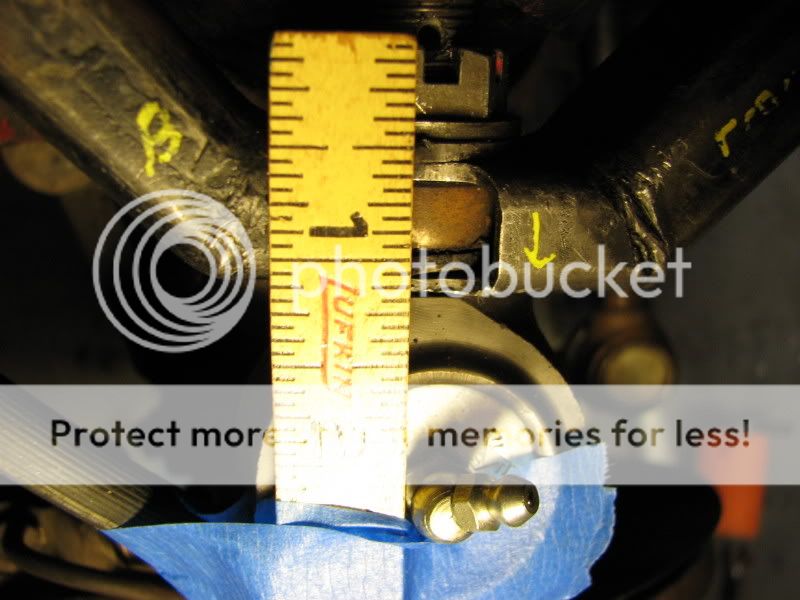

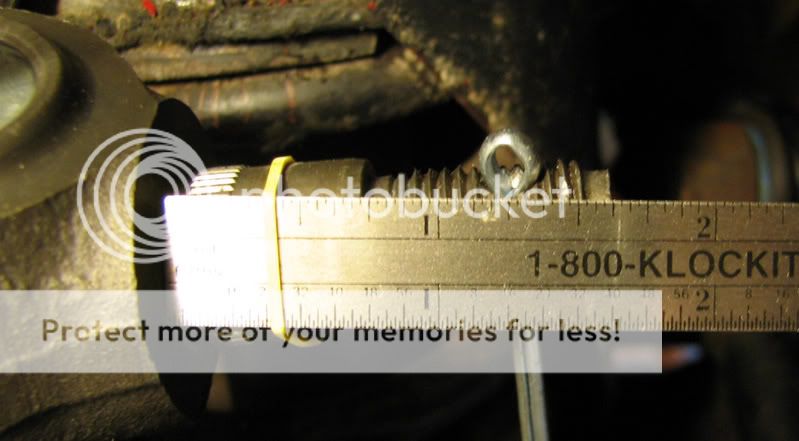

Here's the replacement ball joint from BPNW. As you can see, it uses a nyloc nut instead of a castle nut. It does not include a washer. Should I go ahead and use the old one (shown in first pic)? Haynes does not have a torque for the nut. Really, really tight, eh, with blue loctite?

Cheers,

Adrian

TS 58324

Look what happened to the bolt from the ball joint splinter. Ha!

It's the bolt on the bottom. Then I used an unmarked bolt (colored like a grade 8). That broke as well. Then an old grade 5 - even that bent a little until that pesky ball joint popped. (That's not the original long bolt either - that stripped out when I done the tie rods)

Here's the replacement ball joint from BPNW. As you can see, it uses a nyloc nut instead of a castle nut. It does not include a washer. Should I go ahead and use the old one (shown in first pic)? Haynes does not have a torque for the nut. Really, really tight, eh, with blue loctite?

Cheers,

Adrian

TS 58324

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.