Offline

Hi,

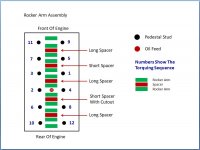

I need to buy a new rocker arm shaft since the one in our car has a groove worn into it by one of the positioning springs. Rocker Arms Unlimited advised me to source a new rocker arm shaft and send it to them before they rebuild the assembly. They usually only reclaim/hard chrome good condition OEM shafts which may not be available used; and they have no information on new shafts.

BTW, our oil pressure is 60 PSI at idle, 50 psi above 2000 rpm when hot and 25 psi at idle when hot (using 20-50 oil). So, we are only having the assembly rebuilt due to the groove being worn into the shaft.

I have not replaced a Healey rocker arm shaft before and I am not familiar with the quality of new replacement shafts. Is it better to (i) buy a new (not chrome plated) hardened shaft, (ii) find a new rocker shaft that IS hard chrome plated or (iii) try to find a used OEM shaft that Rocker Arms Unlimited can reclaim and hard chrome.

Thanks for any thoughts and recommendations.

Regards, Bill

I need to buy a new rocker arm shaft since the one in our car has a groove worn into it by one of the positioning springs. Rocker Arms Unlimited advised me to source a new rocker arm shaft and send it to them before they rebuild the assembly. They usually only reclaim/hard chrome good condition OEM shafts which may not be available used; and they have no information on new shafts.

BTW, our oil pressure is 60 PSI at idle, 50 psi above 2000 rpm when hot and 25 psi at idle when hot (using 20-50 oil). So, we are only having the assembly rebuilt due to the groove being worn into the shaft.

I have not replaced a Healey rocker arm shaft before and I am not familiar with the quality of new replacement shafts. Is it better to (i) buy a new (not chrome plated) hardened shaft, (ii) find a new rocker shaft that IS hard chrome plated or (iii) try to find a used OEM shaft that Rocker Arms Unlimited can reclaim and hard chrome.

Thanks for any thoughts and recommendations.

Regards, Bill

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.