glemon

Yoda

Offline

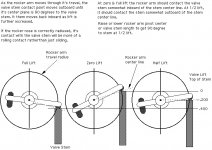

I am rebuilding the motor of my 100 BN1, I had the cam reground to M spec, neither the cam shop nor my machinist mentioned this, but the our local sports car mechanic/guru said I should do something about the rocker arm geometry change.

Should I?, I assume shaving the pedastals a hair would be the best way to put the geometry back to where it had been before.

Should I?, I assume shaving the pedastals a hair would be the best way to put the geometry back to where it had been before.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.