T

Tinster

Guest

Guest

Offline

My new rocker arm shaft arrived today . HooRah!!!

(double mailed to save the $60. seller shipping charge)

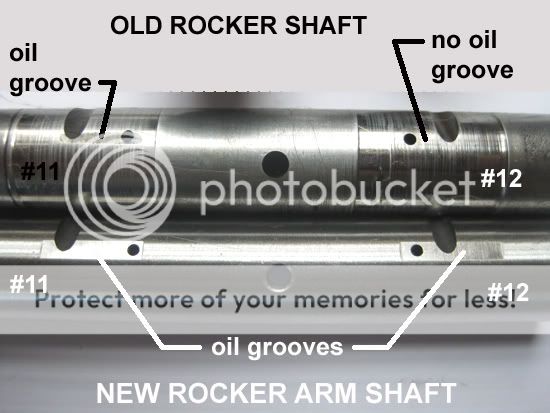

Here's a photo side by side of old and new shafts at

rockers No. 11 and No. 12. Clearly the rocker shaft that

I removed was defective when it left the point of manufacture.

The missing oil groove explains dry rocker No. 12 and low oil

pressure that resulted in dry Rocker No. 1.

I can't wait to put everything back together and see how things

are supposed to operate. PS: Paul- both shaft ends

are threaded to accept hex socket, tapered end bolts.

regards,

dale(Tinster)

(double mailed to save the $60. seller shipping charge)

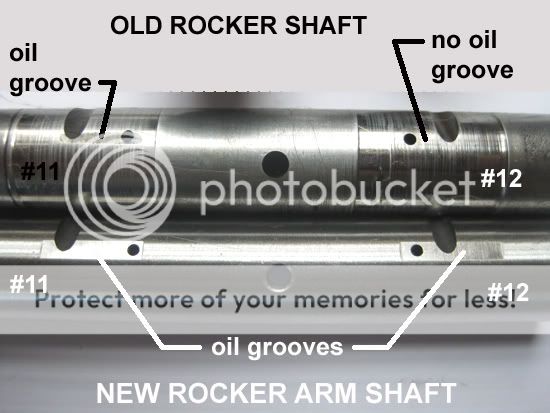

Here's a photo side by side of old and new shafts at

rockers No. 11 and No. 12. Clearly the rocker shaft that

I removed was defective when it left the point of manufacture.

The missing oil groove explains dry rocker No. 12 and low oil

pressure that resulted in dry Rocker No. 1.

I can't wait to put everything back together and see how things

are supposed to operate. PS: Paul- both shaft ends

are threaded to accept hex socket, tapered end bolts.

regards,

dale(Tinster)

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.