AUSMHLY

Yoda

Offline

Hello. This is my first attempt at adjusting the valves.

The shop manual states use of a .012 gauge, screwdriver and wrench, but does not mention how to get the valves in the positions needed.

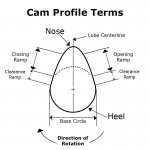

1) What's the best/easiest way. I've used the starter solenoid, but it's a or miss knowing if the valve is in it's lowest position.

Per Youtube, some car manuals state there is an order of which valves to adjust.

2) Is there a valve adjustment order for the Healey?

3) Can two valves be adjusted at the same time? Example, when adjusting valve #1, valve #12 should be in it's lowest position. I noticed valve #10 seemed to be in it's lowest position at the same time too. Was it? If so then I could adjust valve #3 at the same time?

Anything else I should be aware of?

The shop manual states use of a .012 gauge, screwdriver and wrench, but does not mention how to get the valves in the positions needed.

1) What's the best/easiest way. I've used the starter solenoid, but it's a or miss knowing if the valve is in it's lowest position.

Per Youtube, some car manuals state there is an order of which valves to adjust.

2) Is there a valve adjustment order for the Healey?

3) Can two valves be adjusted at the same time? Example, when adjusting valve #1, valve #12 should be in it's lowest position. I noticed valve #10 seemed to be in it's lowest position at the same time too. Was it? If so then I could adjust valve #3 at the same time?

Anything else I should be aware of?

Last edited:

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>