trrdster2000

Luke Skywalker

Offline

Hi all,

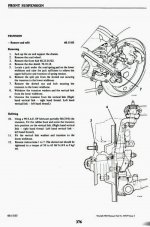

It's been a while but getting ready to replace the seals and plastic bushing on the TR6 trunnions on the rust bucket my buddy got a month or so ago. I generally tighten the nut until it looks like the top seals are just before getting ready to crush and put the split pin in. I can find no torque setting for the application and just wonder if I have been doing it wrong all these years. I do know I will be using the copper non seize on all parts, found this stuff working on BMW's with all the aluminum parts that want to oxidize together.

Any help greatly appreciated.

Wayne

It's been a while but getting ready to replace the seals and plastic bushing on the TR6 trunnions on the rust bucket my buddy got a month or so ago. I generally tighten the nut until it looks like the top seals are just before getting ready to crush and put the split pin in. I can find no torque setting for the application and just wonder if I have been doing it wrong all these years. I do know I will be using the copper non seize on all parts, found this stuff working on BMW's with all the aluminum parts that want to oxidize together.

Any help greatly appreciated.

Wayne

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.