SMGoose

Senior Member

Offline

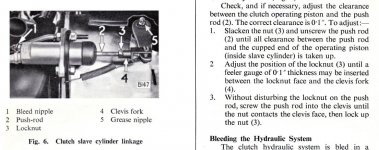

Opinions requested: While pulling out the gearbox on my TR4, I noticed there was no spring or anchor from the slave cylinder to the operating shaft (#s 20 and 21)

I ordered new ones when I ordered clutch components, but I heard that sometimes that spring keeps the clutch from fully disengaging (or something to that effect) and that I should just leave it off.

Also my push rod is not adjustable like the one pictured, it's just a solid rod and fork. The other thing worth mentioning is that I'm putting in a TR6 gearbox which has the thicker flange.

Is this just one of those "see how it goes" type of things and adjust according to trail and error? Or does anyone have particular experience in this area?

I ordered new ones when I ordered clutch components, but I heard that sometimes that spring keeps the clutch from fully disengaging (or something to that effect) and that I should just leave it off.

Also my push rod is not adjustable like the one pictured, it's just a solid rod and fork. The other thing worth mentioning is that I'm putting in a TR6 gearbox which has the thicker flange.

Is this just one of those "see how it goes" type of things and adjust according to trail and error? Or does anyone have particular experience in this area?

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.