Ah, the definition of run-on. But how does it stall the engine? Does it vent the canister to a port below the throttle plates on the original carbs, preventing additional fuel draw through the idle circuit?

Yes, exactly.

I'm guessing the center nipple on the canister is the outlet to the intake manifold side of the carbs? Since this hose is missing (as are the carbs, actually), I actually have no idea to where it originally went.

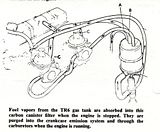

The original carbs had a special port used for the purge line, which was above the throttle plate but below the venturi (so exposed to a constant, low level vacuum with the engine running). The center port of the CC was plumbed to both of those ports, plus the rocker cover.

On my car, those two lights do work, but the oil light is so dim compared to the BRAKE light, I'd never notice it. Was this system really useful when new? If anything, the BRAKE light might draw my attention to the oil pressure gauge right above it. That and I don't have a low oil pressure sender installed either.

Marginal at best, IMO. As you say, it's mostly the brake light that gets my attention. At least on a TR6 you have an oil pressure gauge to check; Stags did not originally come with oil pressure gauges, leaving the driver to puzzle out whether the brakes were failing, or the engine. (Scared me the first time I saw it.) But it was a US safety requirement (I believe) that there be a bulb test function for the brake warning light and this is how BL chose to implement it for a few years. In 76 they finally went to having a bulb test relay (probably because they also needed a bulb test for the EGR service indicator).

Since this solenoid is only activated with the ignition off and the engine spinning - for as long as that would last - when is the CC vented to the engine, to purge the fuel vapors? I noticed a small vacuum port on the valve itself, but it doesn't move with vacuum applied. The solenoid and valve function on my car when I short the wire for the pressure switch to ground.

The purge line is always open (although IIRC there are supposed to be restrictors on the carb ports that limit the flow slightly). The vacuum port on the valve goes to manifold vacuum and gets used only to kill the engine after the key is turned off.

I would like the CC and the fuel tank venting to be functional, as I despise that fuel smell. Unfortunately the Weber MCHH carbs equipped now do not have a vent port for the fuel bowls.

As long as the bowls are vented into the air filters, you probably won't get much smell from them (unless hot soak is boiling the fuel, a common problem these days). Without support from the carbs, I think you're stuck on that point. (Although a really clever and determined person might figure out how to add support to the carbs, perhaps by blocking off the existing vent and drilling a new one to be fitted with a solenoid.)

But for the tank vent, all you really need is a source of vacuum for a purge line (like that banjo fitting on the intake manifold), with a suitable restriction so it doesn't mess up the mixture too much. Lots of cars from the 70s and 80s used little restriction modules for this and that, or I'm sure you could fab one on your own. It doesn't need to be any more than a bit of brass that fits snugly inside a hose, with a hole drilled through it.

https://www.oreillyauto.com/site/c/...+restrictor_-1_3062&keyword=vacuum+restrictor

Or you could even use a needle valve if you wanted real-time adjustability

https://www.mcmaster.com/?m=true#angle-needle-valves/=wjg2ja

That hex head "Whats this" in your photo is the oil pressure relief valve. It keeps the oil pressure from going too high.

Some years ago I got to watch the initial startup of a rebuilt Toyota motor where the relief valve had gotten blocked off by an unwise substitution of parts from different years. It would literally blow the oil filter can off the fitting just a few moments after starting! I don't think the professional mechanic who did the rebuild was very happy with me for pointing out the problem (even though I also showed him how to fix it). He quit the job soon afterwards

Although that might have had something to do with the shop owner docking him for the 15 or so quarts of oil that got dumped on the floor, plus 3 ruined filters.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.