This bothered me for several years...the right edge of the commission was trimmed by hand. I initially thought this was some PO. Since then I have seen many, many pictures of the same trimming on other TR2's. I now firmly believe the factory did this to clear the RHD blanking plate. Another Standard MC quirk!?!

3/16" pop rivets. I am sure the perfect rivets are available...somewhere. I simply use standard large head rivets, but do not pull the rivet until the center breaks off. I only pull them until they are firmly held in place.

I then use a dremel cutoff disc to cut the center posts out. You would have to look very closely to tell any difference between these and the originals.

I am wrapping the top of the steering column so it will not get scratched while it slides through the firewall.

Do not forget to feed the sealing boot and clamp before running it through.

You may have figured out that there is a reason to the order of the last several parts. To save having to thread some lines/hoses, etc. in and around, you should intentionally install in this order, which is apparently the order the factory used:

1) Hard hydraulic lines.

2) Odd lines for speedo and tach.

3) Electrical harness.

4) Soft hoses.

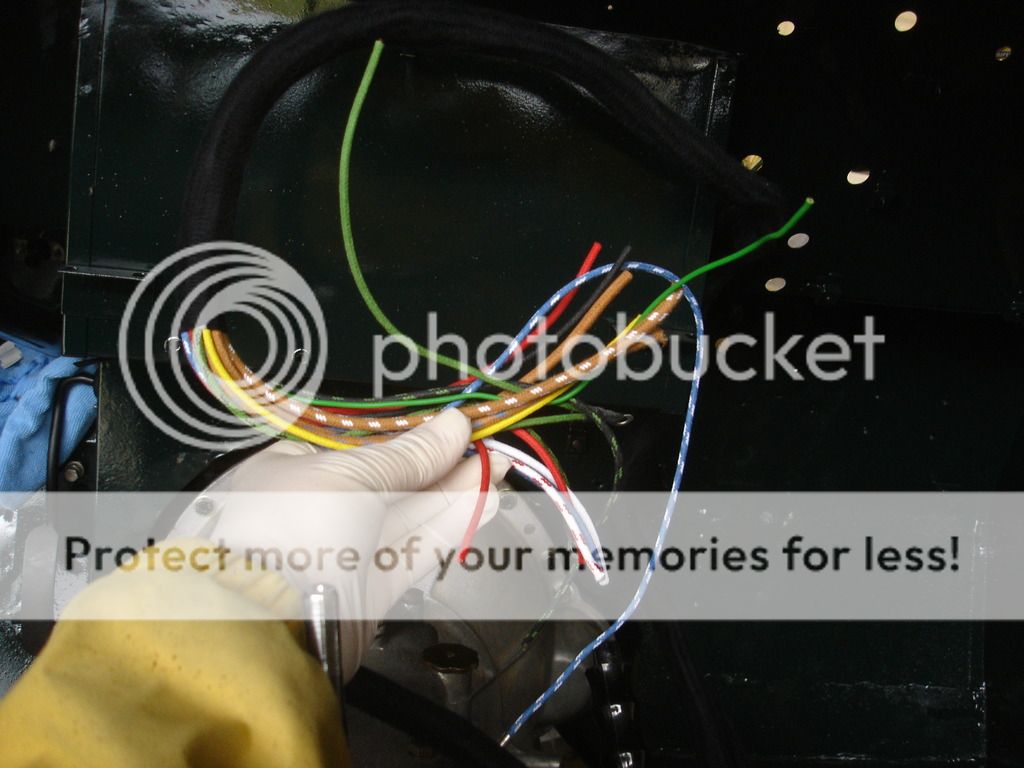

So, let's continue with the wiring harness.

Start in the cabin, and feed the largest bundle of free wires through from the cabin on the right side of the firewall. The Moss harness even has a grommet to help you locate this particular bundle.

In the cabin to the left of the passenger's feet. The harness splits into a thick bundle and a thin one. The thin is the tail light bundle, so it will separate and go to the right. The thick bundle goes left.

Next, the thick bundle splits again. The split with the wire fray goes to the front of the battery box and gets held with the body cable ties. This will feed all the instruments later.

This is the long, thin bundle crossing the passenger's feet well to the right. The body has built in cable ties to hole it as it goes.

We tie it around all the way on the right side of the body and to the boot.

The green striped wire popping out in the last pic goes to the fuel tank sender.

And on around all the way to the tail lights.

Now, the loose bundle gets stuffed forward of the battery box. It will be out of sight after it it is tied in place.

It goes over the steering column. Notice the column is padded with a rag at the firewall, since it is not held up by the dash...yet.

The bundle splits again. The long split goes back out the firewall. You will need to buy a grommet for this split.

The shorter split with the blue motif goes on around to the dimmer switch.

Don't forget to look for the provided cable ties on the body. Hmmm. If you remember in my body thread I pulled the ties up a bit before painting, so as to get paint all around them. I missed this one!! Bummer.

Now we can install the second firewall grommet.

Once the grommet is installed, you continue in the left side engine bay, tying the final bundle around the inner wheel well.

The left ends here, at the horn mounting pad.

Back in the cabin, we have to tidy some of the runs. This is over the driver's right foot, where the dimmer bundles splits from the through-firewall bundle. You must spread them enough to have access to the heater through fitting later, when the heater hoses are installed.

Found the tach cable!

It passes through the left side 1" hole behind the oil pressure flex hose, and uses a grommet. The other hole is for the temp sender capillary tube.

And the front is screwed to the distributor.

Hey there Guest!

Hey there Guest! A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.