Rut

Obi Wan

Offline

I rebuild my 1970 MGB engine over the summer with a parts kit and advice from Hap and a machine shop owned by an MG enthusiast and friend. The reason for the rebuild was due to the engine sitting for years and the cam and lifter on valve #1 eating each other. The engine was bored .060 over, VP12 cam and short lifters/long pushrods, vernier cam gear and double row chain, 38cc Marina head with intake valve enlarged to 1.625", hardened seats and CR at 9.5:1. All the usual machine shop work performed and the engine ballanced, main and rod bearings .020, King bearings, etc...

I assembled the engine myself with Hap and the machine shop checking each and every stage, measured bearing clearance with Plastigauge, and everything checked and rechecked. Oil pressure on starter 50 psi + and once running 70 psi cold, 60 psi hot idle. Engine broken in with VR1 oil (high ZDDP) for 25 min at 2500 rpm and all readings normal throughout.

Once broken in and carbs/timing set the car idled at 1100 rpm and ran great, plenty of power and very responsive...everything I wanted. Im using the original rebuilt SU HS4s and they were set a little rich, but work really well.

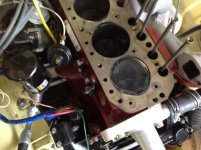

Now, all that being said I developed a light rattle from the engine above 3500 rpm on a drive yesterday morning and stopped by the machine shop for a little help. The noise was diagnosed as a main bearing and the oil filter was pulled and cut apart to confirm. Oil smelled of gas and the SUs were cursed by the shop! Oil pressure is still at 60 psi and it was deemed ok to drive the 3 miles home to pull the engine, so I head home at 2000 rpm with no noise. I make it about 1 mile before the rod comes thru the block on number 1, the original lifter/cam failure site.

Once the car is home and up on jack stands I begin disassembly, drain the cooling system, etc. When I pull the carbs and intake manifold, both manifold throats are soaking wet with gas. I'll go over the carbs to correct that issue, but is that enough to cause an issue like this due to oil dilution?

Hap wants pictures at each stage of the tear down so he can help figure out what went wrong. Well, I got 90 miles of grins before this happened and I now have a winter (70 degrees today) project!

Rut

I assembled the engine myself with Hap and the machine shop checking each and every stage, measured bearing clearance with Plastigauge, and everything checked and rechecked. Oil pressure on starter 50 psi + and once running 70 psi cold, 60 psi hot idle. Engine broken in with VR1 oil (high ZDDP) for 25 min at 2500 rpm and all readings normal throughout.

Once broken in and carbs/timing set the car idled at 1100 rpm and ran great, plenty of power and very responsive...everything I wanted. Im using the original rebuilt SU HS4s and they were set a little rich, but work really well.

Now, all that being said I developed a light rattle from the engine above 3500 rpm on a drive yesterday morning and stopped by the machine shop for a little help. The noise was diagnosed as a main bearing and the oil filter was pulled and cut apart to confirm. Oil smelled of gas and the SUs were cursed by the shop! Oil pressure is still at 60 psi and it was deemed ok to drive the 3 miles home to pull the engine, so I head home at 2000 rpm with no noise. I make it about 1 mile before the rod comes thru the block on number 1, the original lifter/cam failure site.

Once the car is home and up on jack stands I begin disassembly, drain the cooling system, etc. When I pull the carbs and intake manifold, both manifold throats are soaking wet with gas. I'll go over the carbs to correct that issue, but is that enough to cause an issue like this due to oil dilution?

Hap wants pictures at each stage of the tear down so he can help figure out what went wrong. Well, I got 90 miles of grins before this happened and I now have a winter (70 degrees today) project!

Rut

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.