I had no luck, so I had David Nock mate my OD to my gearbox last year. He removed the pump; for inspection and to make mating the units easier. His mechanic screwed a couple of long (3+") screws of the proper thread into the two holes and used some sort of puller--sorry, don't remember the exact tool (think I might not have been watching)--to extract the pump (I think you might make do with a small slide puller somehow).

When I replaced my accumulator with a DWR 'uprated' unit, I noticed that the walls of the old cylinder were somewhat scored--the piston has metal rings--and this could result in a loss of pressure, so you might have to replace the whole unit. My pump was OK, with over 200K miles, and they're bathed in oil so as long as no grit gets to them they should last. My guess would be either your accumulator cylinder is scored, or the ball check-valve on the pump isn't seating well. It sounds like your pump can produce sufficient pressure, but something is relieving it when RPMs drop. Best guess is the check valve.

So, you were able to get the accumulator piston out without pulling the OD? I may have to do this as well, as the new O-rings I installed appear to be leaking.

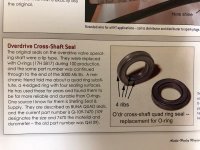

Side note: don't get me wrong, Moss is a great company for us owners, but the last few seals and O-rings I've bought from them have been 'close but no cigar.' Probably, exact replacements--like for steering box shaft seals--are NLA, so they stock the closest thing they can get. Unfortunately, there is no such thing as 'close enough' with seals and O-rings. I replaced the operating shaft O-rings and, sure enough, at least the outside one is leaking. The following is by Roger Moment--acknowledged Healey guru--and found in the latest

Austin-Healey Magazine:

I bought some of these--ordering was, uh, a 'challenge'--so send me your address in a PM and I'll mail you a couple if you like.

Edit: One other thing occurred to me: The two pistons that push the OD cone clutch into the brake ring have rings as well; I believe older cars use metal ones, and newer ones have O-rings, but I think they're only in play when you engage the OD, but might bleed down too fast if the rings/O-rings are worn or their cylinders are scored.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.