KVH

Darth Vader

Offline

Well, I know it's not all that exciting.

But I have two leaks from the overdrive unit in my TR4A. As Randall suspected, neither has anything to do with the silver BBs or freeze plug.

The first is not so unusual--dripping from the OD drain plug. I'll mess with that as best I can.

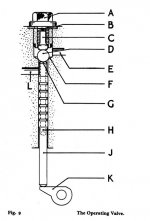

The second is from a small lever on the passenger side of the OD housing. Moss seems to refer to that piece in a Troubleshooting Note as the "adjustment setting lever."

Anyway, I assume I can't do anything about this leak short of pulling the transmission. I can't tell from the Moss drawings but there may be an 0-Ring or bushing for the shaft.

I've lost 6 ounces of fluid while the car sat for 4 months, so this definitely is a constant drip. I'd guess half from the plug and half from this little lever.

I'll follow any good advice (like forget it, drive, top up, drive).

But I have two leaks from the overdrive unit in my TR4A. As Randall suspected, neither has anything to do with the silver BBs or freeze plug.

The first is not so unusual--dripping from the OD drain plug. I'll mess with that as best I can.

The second is from a small lever on the passenger side of the OD housing. Moss seems to refer to that piece in a Troubleshooting Note as the "adjustment setting lever."

Anyway, I assume I can't do anything about this leak short of pulling the transmission. I can't tell from the Moss drawings but there may be an 0-Ring or bushing for the shaft.

I've lost 6 ounces of fluid while the car sat for 4 months, so this definitely is a constant drip. I'd guess half from the plug and half from this little lever.

I'll follow any good advice (like forget it, drive, top up, drive).

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.