This one is for you Frank!

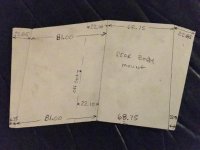

Proceeded with the base of the spare wheel carrier. To do the depression in the base, I drew a circle at the limit of the depression. At this stage I did not worry about the depression which extends to the rear opening, the idea being to get a uniform depression in place and then extend it rearwards when happy with the depth and quality of the work.

Hammered out the depression on the sand bag and then tidied it up on the English wheel. Then back to the sand bag and with the blocking hammer I extended the depression as far back as needed. Tidied this up on the wheel.

The rear lip where it joins the apron is depressed accross the width of the panel and there is a secondary depression in the middle for a tie down for the wheel. (I think). These I formed with the hammer and dollys and a couple of old bolts modified as punches. The outer edges were abused in the bench vice as well. (Those of you who know your wheel carriers will have spotted that the rear depression could be a little wider to fit the curved profile of the box section that goes under it. This has been noted and will be attended to!)

Decided in for a penny, in for a pound and moved on to the rolled edge on the outer perimeter.

Marked the depth of the curve around the perimeter and then used the tuck fork to put a series of puckers around the perimeter. Hammered these out on the wooden block to shrink the outer edge.

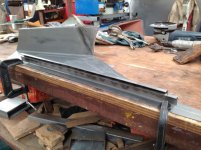

This is how it looked straight off the block. Not pretty but the curve was there.

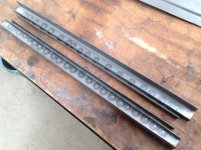

I have a stake made from a piece of one inch galvanised pipe which suited the curve here so I tidied up the curve on the stake. In rolling the edge over the stake, there was a tendancy for puckers to form naturally on the outside of the curve. These I worked back into the metal on the stake improving the shrink on the roll.

This is how it came off the stake. At the time I also rolled over the straight sides to the rear as these did not require shrinking. I also tidied up any walnuts in the metal where I may have mis-hit when trying to do the shrinking. (I guess it was me)

About this point I decided it was time to move to the English wheel and roll it into a perfect curve. Ufortunately when I checked, I don't have any wheels that are tight enough radius to fit in the rolled edge.

So, hammer and dolly it is. I used the pipe stake as a hand dolly and proceeded to work the edge around with a panel hammer. This formed some more puckers naturally as I worked the metal into the curve so I put the stake back in the vice and worked the puckers back into the metal.

When happy with that, I found a dolly in my box of bits that fitted the rolled curve perfectly on the old spare wheel carrier. I worked around the perimeter with the hammer and dolly to finish it to the point where it can be welded to the wall sections. If you check the photo below, you will see there is virtually no sign of the puckers in the edge of the metal which shows what can be done with the basic tools.

I still have to roll the sides at the rear of the panel where it protrudes through the rear apron. This is a different radius to the major perimeter roll. Also, the height of the rolled edge now needs to be scribed and trimmed, ready to accept the walls of the carrier.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>