Hi Frank, I guess we are talking about the rear wing. Unfortunately I didn't take enough photos of this work. Didn't realise it would create the interest it has. So the photos I have don't show the detail I would like.

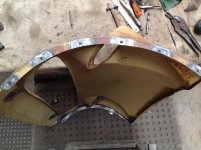

The wing requires a combination of both stretching and shrinking but in the first instance is just a straight roll along the top shoulder and a straight roll down the back end, nearly at right angles to each other. I just rolled both over a length of about four inch pipe I clamped to the edge of my bench. The rolls get a bit crowded at the tail light area where they meet so I then went into some severe shrinking in that area to blend the rolls together. When I got the rough shape of the tail light section I then used the shrinker stretcher on the flat part of the section to pull that area in tight. You need to cut away any excess metal to simplify the shrinking. Once I had roughed out the shrink in that area, I then started stretching back into the body area on the sand bag to give it some body. You can see the "walnuts" in the photo below from the ball pein / blocking hammer.

You need to be careful with the shrinking though. I always worry about getting enough shrink and then over do it. I find it harder to stretch the metal back nicely after too much shrink as the shrinking work hardens that area. So a bit at a time. The shrinking is done with a tuck fork to put tucks in the metal and then hammering in the shrink with a blocking hammer on a hard wood block. After work on the sandbag, I wheel it to check that the shape is forming correctly. Might then need some more hammer / sand bag work to continue getting the shape. Don't over do it though because the wheel will also add body to the shape without much pressure.

From there I used tucks and the hammer to shrink in the bottom corner a bit but not too much. I also used the hammer and sand bag to balloon out the back of that area a little, rolling it on the wheel to keep it smooth and allow me to see it taking the shape slowly.

The curvature of the back section is also determined by the rear flange. As soon as you put the flange on it, you stuff up the shape. Applies to the top section as well. The shape is recovered by shrinking / stretching the flange accordingly to bring the curvature back into the panel. The critical thing though is to not put any flanges in place until you have the shape fitting the buck. You play with the flange to recover the shape you have already put into the panel. (The exception is when you want a flange to lock in the shape. Eg hold the edge straight or to a pre determined curve)

Getting the rear bottom curve / corner right was done by shrinking the flange in that area to pull the rear edge in. I cut myself a little profile to match a good wing and then kept shrinking a little at a time and repeatedly checking against the profile until the bottom edge matched nicely.

It does not look like there is a lot of curvature in the panel but there is the same as the originals. Also, the final shaping will be done by tweeking the flages when the panel is fitted to the car.

I hope some of this makes sense. Happy for others to offer suggestions because I'm just finding out as I go. Would love other guidance that clarifies things to help Frank out and add to my small collection of techniques.

So Frank, keep at it but take it slowly. When I started the rear panel of the car, I walked away from it and it sat next to the car for about six months before I worked up the courage to go back to it. The final panel is the same piece of metal I started with. Sometimes you have to think about it a bit more and then give it another go. All you can do is lose a bit of time and a small sheet of metal.

Sat like this for months

Ended up like this

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>