T

Tinster

Guest

Guest

Offline

I am starting this thread for all

the guys like me who have almost no

basic automotive repair experience.

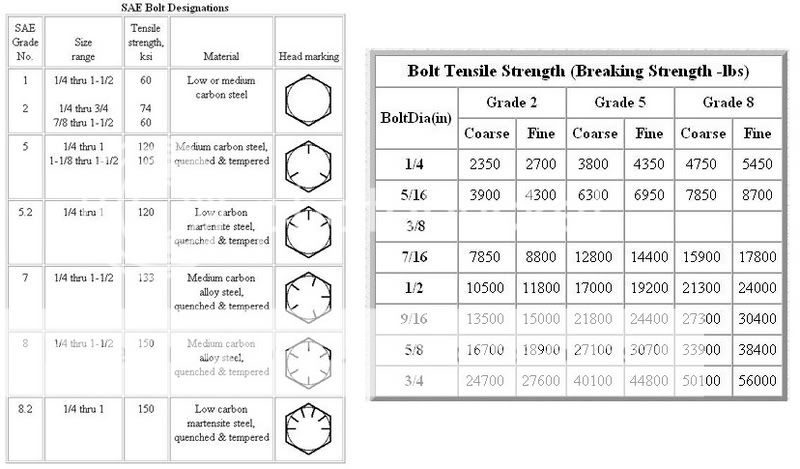

1. It took me a while before I learned there

should be NO metric nuts and bolts in my car.

2. So I started taking out all the new metric fasteners

and replacing them with stainless steel American/Brit

nut and bolts and lock washers.

3. Found out THAT was wrong too. SS too weak for most

things.

4. So Once again, I stared taking out the SS and

replacing with high strength #8 steel and nyloks nuts.

Now I find out the nyloks are not correct.

Oh yeah, I forgot. Brass nuts and bolts are not to used

either.

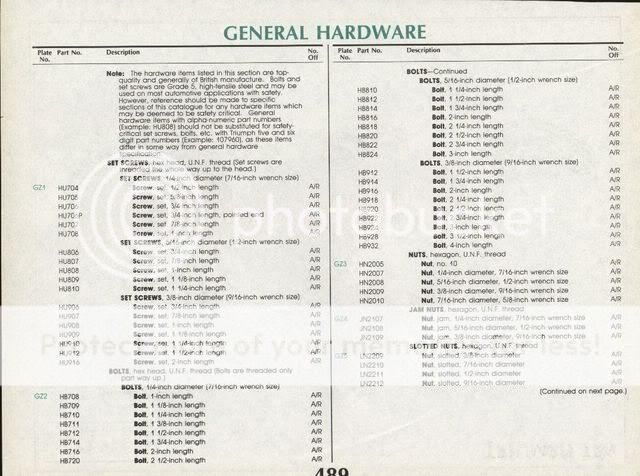

So all you TR guru experts out there: How about some

advice for us beginners as to how to replace fasteners

in our TRs?

As always, thanks so much,

Dale in kinda cold 78* Bayamon, PR

the guys like me who have almost no

basic automotive repair experience.

1. It took me a while before I learned there

should be NO metric nuts and bolts in my car.

2. So I started taking out all the new metric fasteners

and replacing them with stainless steel American/Brit

nut and bolts and lock washers.

3. Found out THAT was wrong too. SS too weak for most

things.

4. So Once again, I stared taking out the SS and

replacing with high strength #8 steel and nyloks nuts.

Now I find out the nyloks are not correct.

Oh yeah, I forgot. Brass nuts and bolts are not to used

either.

So all you TR guru experts out there: How about some

advice for us beginners as to how to replace fasteners

in our TRs?

As always, thanks so much,

Dale in kinda cold 78* Bayamon, PR

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.