doughairfield

Jedi Trainee

Offline

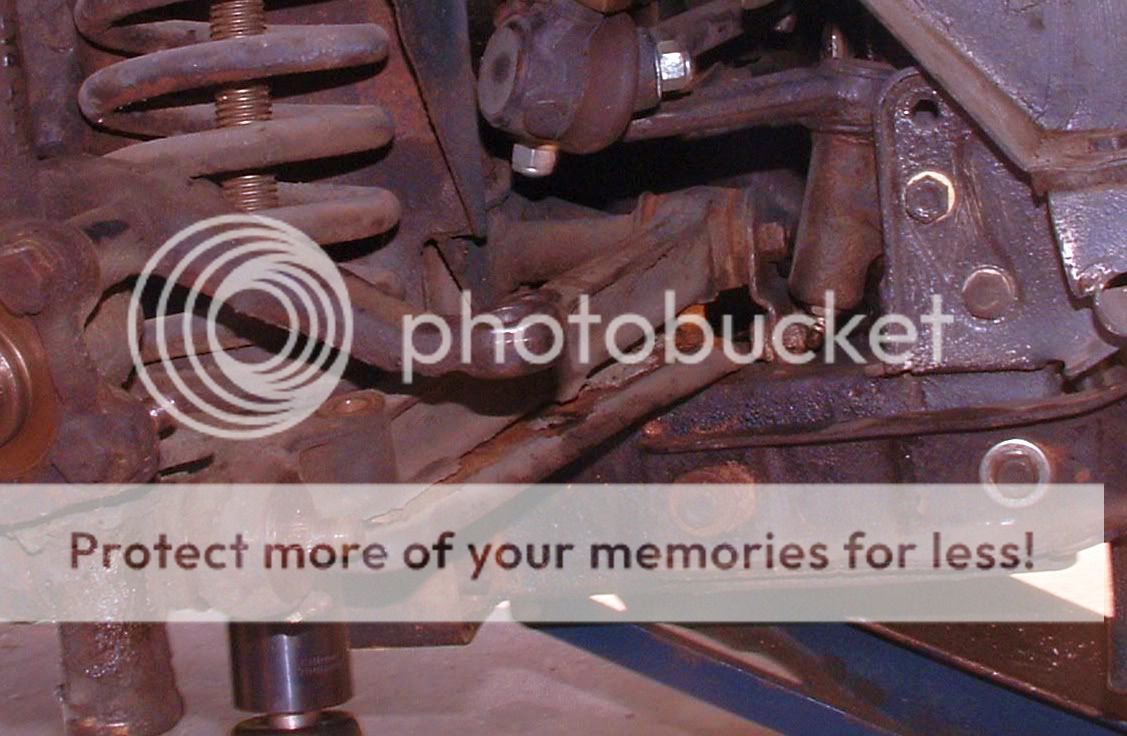

I'm on the home stretch of putting new trunnions on my 64 TR4, but I've got one question.

On the lower A-Arms, trunnion end, there is a locking washer that is the final piece you put on before the slotted nut, but it's inner diameter is too small to slide over the "arm" of the trunnion. Do you have to ream these locking washers to fit as you do the A-Arm bushings, or do they just press in forming a seal once you tighten the slotted nut down?

On the lower A-Arms, trunnion end, there is a locking washer that is the final piece you put on before the slotted nut, but it's inner diameter is too small to slide over the "arm" of the trunnion. Do you have to ream these locking washers to fit as you do the A-Arm bushings, or do they just press in forming a seal once you tighten the slotted nut down?

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.