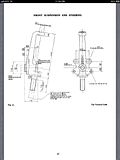

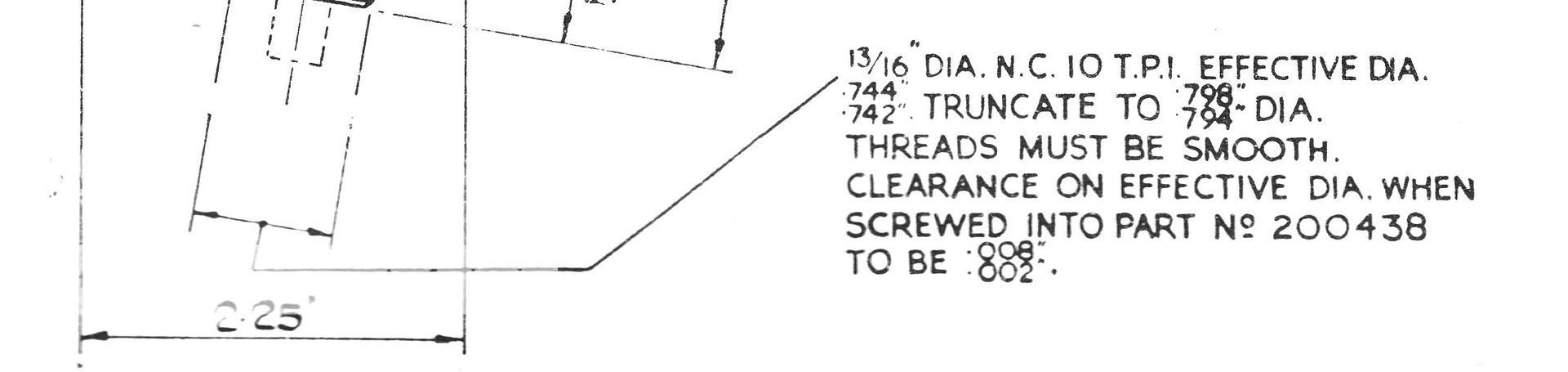

Slowly making my way through the suspension. I am trying now to remove the front trunnion. The manual says removing the steering stop screw and spacer, and unscrew. Did this, but the vertical link body won't allow it to rotate beyond a turn because it hits the trunnion. (Yes, I am turning it the right way :rolleye . I don't want to force it as I don't want to mess up the gear. THoughts?

. I don't want to force it as I don't want to mess up the gear. THoughts?

Also, the manual says to replace the front trunnion and vertical link as a pair. There is a lot of play IMHO in the trunnion, so I bought a replacement. I didn't see the recommendation to replace them as a pair. Holy Cow the vertical link is 259$ from Moss! What do you all do?

~

Also, the manual says to replace the front trunnion and vertical link as a pair. There is a lot of play IMHO in the trunnion, so I bought a replacement. I didn't see the recommendation to replace them as a pair. Holy Cow the vertical link is 259$ from Moss! What do you all do?

~

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.