Healey Nut

Luke Skywalker

Offline

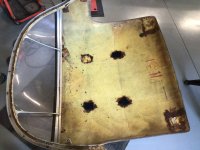

Lighting mock-ups all completed. Rally sump guard done. Grille surround test fitted, ready for rechrome along with my custom-made-by-me trim rings for the upper rally lights.

Next is the rear seat blank-off plates, then she's off for exterior paint once my place in the queue comes up.

Next is the rear seat blank-off plates, then she's off for exterior paint once my place in the queue comes up.

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>