Finally replaced the flange around the rear wheel arch on the left side and spot welded the inner wheel arch to the flange.

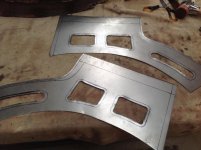

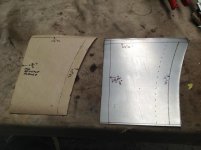

Previously, I said I would show in more detail the fabrication of the one piece patch panel for the lower front of the dog leg.

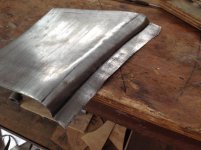

The section has a slight curve in its in its main area both horizontaly and vertically. If the curvature leading to the flange is created from a flat section, a resulting depression will result in the panel. To minimise this effect, the flat section needs to be pre-curved prior to creating the outward curvature. I did this on the English wheel but it could have easily been done with a round mallet on a sandbag. The two black lines are respectively where the rollout will occur and then the reverse flange for the fender mounting surface.

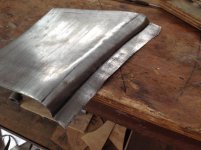

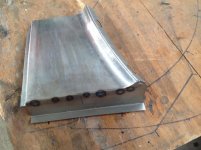

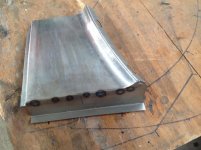

Once the flange was rolled out over a stake with a plastic mallet, we can see the reverse curve the panel has taken. Without creating the pre-curvature, this would be more extreme. To reverse this effect, the large flange needs to be stretched, bringing the correct curvature back into the panel. The line above the ruler is where the reverse flange will be bent.

I used the bead roller to start the bend of the flange. This could just as easily been done on a sharp stake with a mallet but the bead roller was there so I used it. As the flange is rolled over, the outer edge is being forced to a smaller radius and therefore has an excess of metal, indicated by the ripples / waves in the flange. Other side effects are the straightening out of the curve of the fender shape and tightening the radius of the rollout from the flat section.

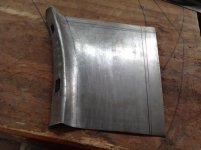

Shrinking the flange has the following effects

flattens the flange

allows the flange to be bent around further

reinstates the fender curvature

opens out the radius of the rollout and

reinstates the nice curvature of the main section.

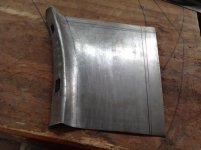

Time bend the reverse flange where the panel attaches at the front of the B post. This was done on a sharp stake in the vice with a plastic mallet. This had to be done on a stake because the sheet is curved in this area and a staight brake to bend the flange would have destroyed the panel curvature. The box section underneath was then added.

Clamped and finally welded in place. Spot welded to the inner sill underneath.

Welded the inner panel in place.

Got to spot the outer sills in place and that is the end of the body tub work!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>