Installed Crane XR700 and cannot get the the engine to fire.

Verified by the #1 plug not showing a spark at the plug.

12VDC is at the coil. Ground confirmed. 6 cyl rotating ring is pushed down all the way, clearance between the optical sensor and the rotating ring is ok.

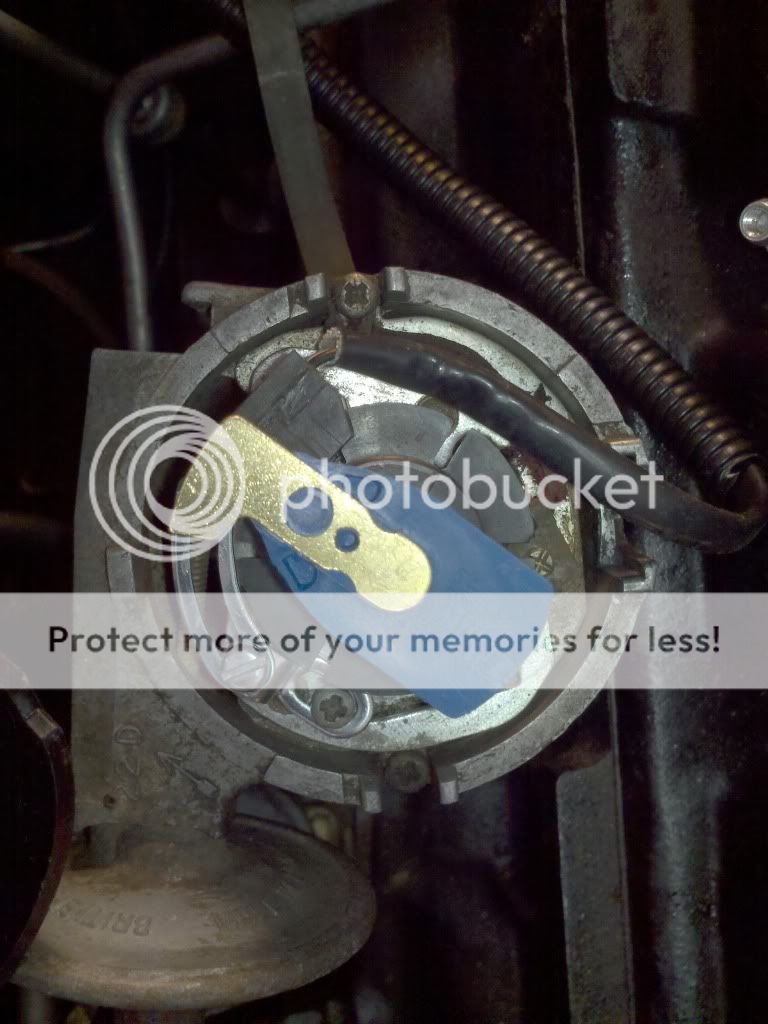

I am not sure if the optical sensor is correctly posiitoned.

I it is possible to look at this pic and see if it looks correct would help. #1 cyl was at TDC. Rotor is in correct position but is the optical snesor correct as this is as far as it can be moved.

The instructions are not clear if the optical sensor has to be lined up with the center of the rotor at TDC.

I used the Condensor mount hole to mount the arm which mounts the sensor bracket. Another pic of a known working circuit may help.

Thanks.

Arlie

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.