Hi Vette,

I totally AGREE that the oil filler cap and dip stick should be Vented and NOT sealed.

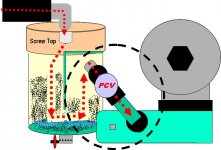

I did find paper notes that indicated the amount of blow-by during initial experimental installations was found to be greater than anticipated at Speed when the amount of vacuum was at its lowest. Upon returning home after a run, the few that initially experimented with a PCV installation, found various amounts of oil had been pushed out of the filler cap and dip stick to cover their engines. Seals were installed onto the oil filler cap and dip stick to reduce this condition and increase directional gaseous flow during times of minimal vacuum with high blow-by (at speed). The results of those actions was to improve the oil blow-by retention and leverage blow-by pressure to add additional force to exhausting gases through the PCV.

Keep in mind that a normal PCV configuration does utilize a vent that must be placed as far as possible from the PCV and is needed to allow 2-way ventilation:

1. Supply Fresh Air at Idle with High vacuum and Low blow-by

2. Exhaust Blow-by at Speed with Low vacuum and High blow-by

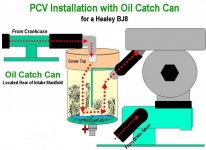

When considering a proper PCV installation (assuming we can identify a proper PCV valve), I would also install an Oil Catch Can on the “T” tube prior to the PCV to extract any heavy oils/vapor from flowing through and contaminating the PCV. I would gain vacuum to the PCV in the same way Bob has, through tubes tapped into both carburetor spacers. Finally, I would install a vent tube into a sealing oil filler cap and connect it, vial tube, to an air filter in a similar way as with the originally rear (could be installed on the front carburetor) to supply either clean filtered air or direct expelled blow-by for combustion...which ever is called for at the time.

Although I feel this configuration would work, as Derek had posted, it is too complex and prone to unintended consequences for me to install on my Healey without a true need. However, I will retain the oil catch can as installed.

Ray(64BJ8P1)

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.