Jim_Gruber

Yoda

Offline

Now a deep dive into the trunk. Bugsy II was hit in the rear it appears as he received a complete trunk floor, and a complete rear clip. The is damage inside of the trunk that was repaired with Pop Rivets. Yep pop rivets. Since it is my plan to put Bugsy II on a rotisserie. I need opinions on what to do with the repairs coming in this thread and how to best address them. The last thing I want to have happen is to have him up on the rotisserie and have the rear clip separate from the rest of the body. This damage I believe is what caused what was originally a RHD BE, No L in the VIN #, to become a LHD BE and emigrate to Quebec sometime in the late '70's. I can see evidence on dash where RHD Steering wheel was connected etc.

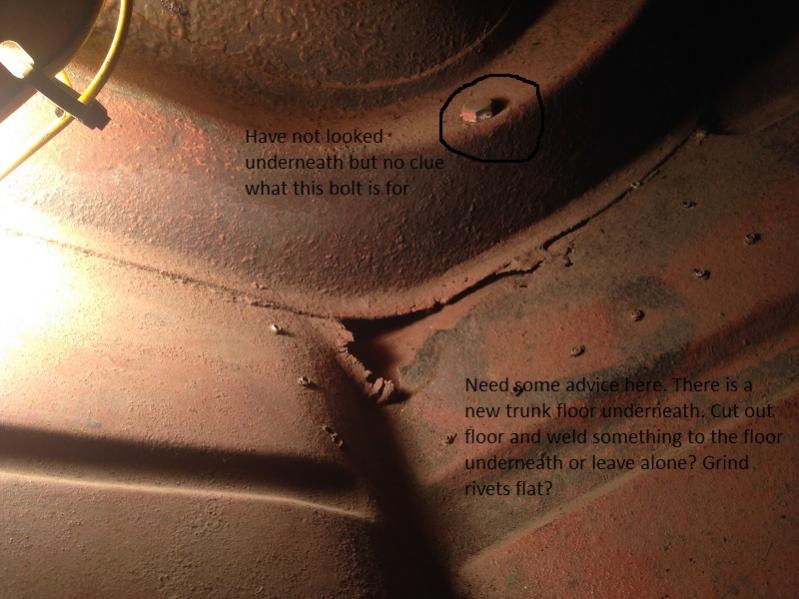

4) Damage on PS behind the wheel hump

There is a strange bolt. May be anchor point for the trunk floor underneath. Rust at bottom of wheel hump and those are pop rivets. I'm assuming holding trunk floor to panel below. How best to fix, need advice. Thinking cutting with grinder and welding a plate over the top. Do I need to attach to panel below in some way. How about the body seam where the brace comes in from the top.

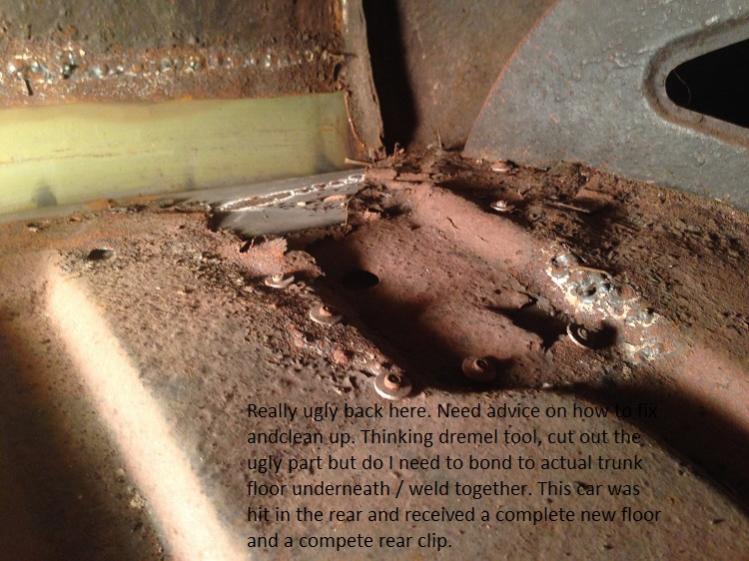

5) Right Rear Floor - Accident damage.

This is ugly back here. Again thinking Dremel tool and cut out and weld in patch panel. Likely needs to attach to back deck or to the floor panel below. Advice needed.

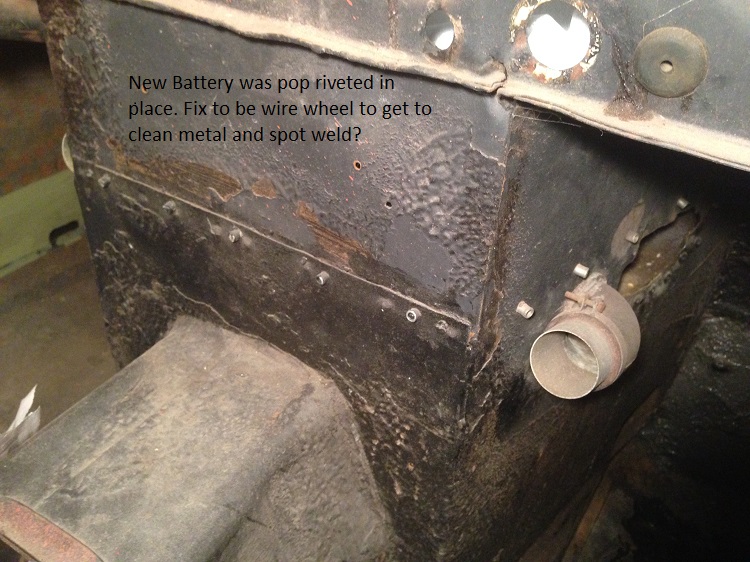

6) Battery Box repair with pop rivets

This should be simplest I think. Tack weld and grind off rivets. On the side will need to weld from engine compartment side.

Rest of Bugsy II is in pretty good shape. Just some advice please on how to tackle some tricks stuff. Thanks in advance.

4) Damage on PS behind the wheel hump

There is a strange bolt. May be anchor point for the trunk floor underneath. Rust at bottom of wheel hump and those are pop rivets. I'm assuming holding trunk floor to panel below. How best to fix, need advice. Thinking cutting with grinder and welding a plate over the top. Do I need to attach to panel below in some way. How about the body seam where the brace comes in from the top.

5) Right Rear Floor - Accident damage.

This is ugly back here. Again thinking Dremel tool and cut out and weld in patch panel. Likely needs to attach to back deck or to the floor panel below. Advice needed.

6) Battery Box repair with pop rivets

This should be simplest I think. Tack weld and grind off rivets. On the side will need to weld from engine compartment side.

Rest of Bugsy II is in pretty good shape. Just some advice please on how to tackle some tricks stuff. Thanks in advance.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

= :eagerness:

= :eagerness: A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.