BugEyeBear

Jedi Trainee

Offline

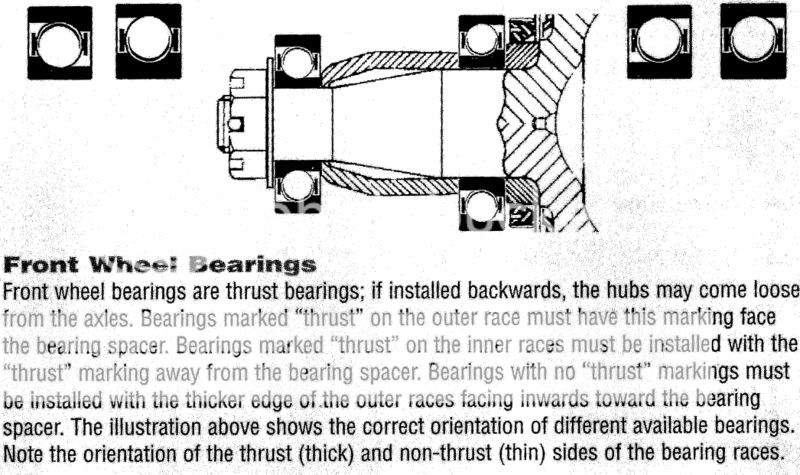

bthompson said:I asked this same question in a thread about 22 pages back...GrahamP uploaded a pic that he got from someone else, so I'll reference it too and keep it circulatin'.

Best illustration I've seen that breaks it right on down.

YUP! That's it!!

-Bear-

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

:lol: <span style="font-weight: bold">We think alike!!</span> :lol:

:lol: <span style="font-weight: bold">We think alike!!</span> :lol: