<span style="font-weight: bold">Kellysguy,</span>

Thanks for the tip about the hardware.

I got the head off eventually by re-connecting the thermostat housing and gently using a crow bar between it and the timing cover flange.

I did get the head off the ole TR3 by cranking the engine with rope stuffed down a plug hole. Valve pedestal was removed of course, so the valves were not going up and down.

<span style="font-weight: bold">Morris,</span>

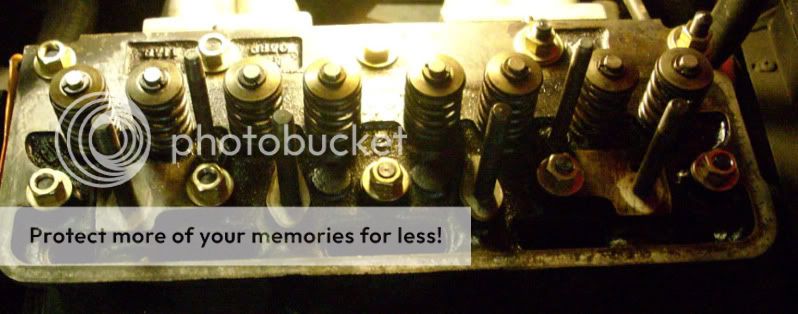

Remind me not to shake hands with you. You must have some grip. I tried channel locks then vice grips but no luck. 5 studs came out no prob with double-nutting. The other bad boys are soaking in PB Blaster.

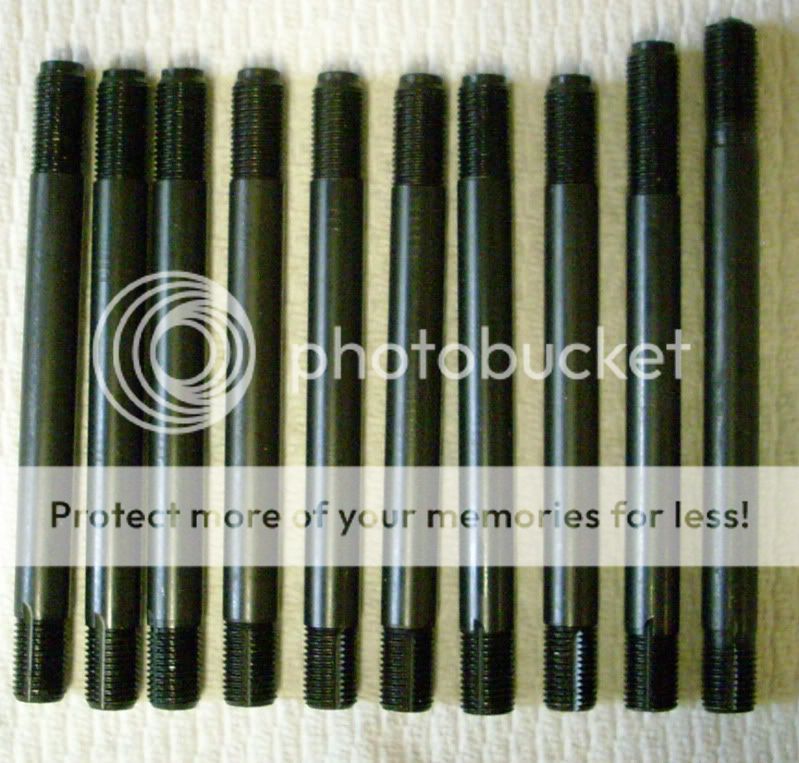

Wow, yeah, good deal on the ARP set. It says 5 days before shipping though and the gal wants to pick the car up soon so there is a bit of a time constraint. I went with the set from BPNW - half the price of Moss Motors. Lets hope its not half the quality. Ha!

Will try your method again tomorrow on the studs.

Cheers!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<