bigjones said:

If the studs hold, after firing the engine up, I will tear it down and put in a new gasket. Does that sound like a plan - or another dumb move?

Let's think about this for a moment. If the studs hold....how will you know, by the used gasket not leaking? So... if it leaks...is it the used gasket or the studs?

The block threads are marginal to begin with; rememeber what I said about only being able to go together once? Why chance it? If this indeeed is your plan, use a new gasket and studs and LEAVE IT BE if it works.

Another thought, say it works....for now, when it runs warm again, "pop goes the weasel". (maybe)

IF...and only if, you have enough GOOD threads in the block as much as the nut is tall, AND....a new gasket....AND you don't keep pulling it back apart, MAYBE....just maybe..it'll hold. (with new studs of course)

If it doesn't hold, you're out your new studs (however many you change) and a new gasket. You 'll need those again as well as heili coils and a possible a machine shop bill.

Remember, never enough time and money to do it right, but always enough time and money to do it twice.

Above all, DON'T FEEL BAD !!!! Strip happens.

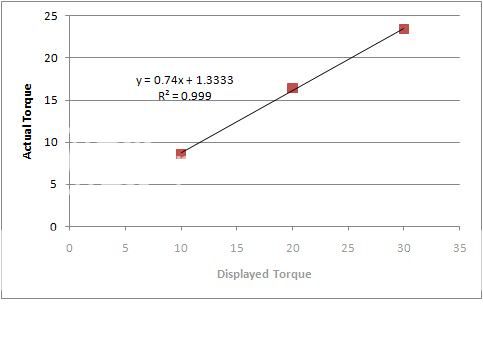

I would think a stored-loaded torque wrench would read under, not over. I think it came in this way. It's not your fault, so don't feel bad. It's just one of those things that happens some times....just this time it's happening to you.

Maybe this is an attractive lady friend, and bigjones wants an excuse for her comming over, 'eh??? :wink:

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>