G

Guest

Guest

Guest

Offline

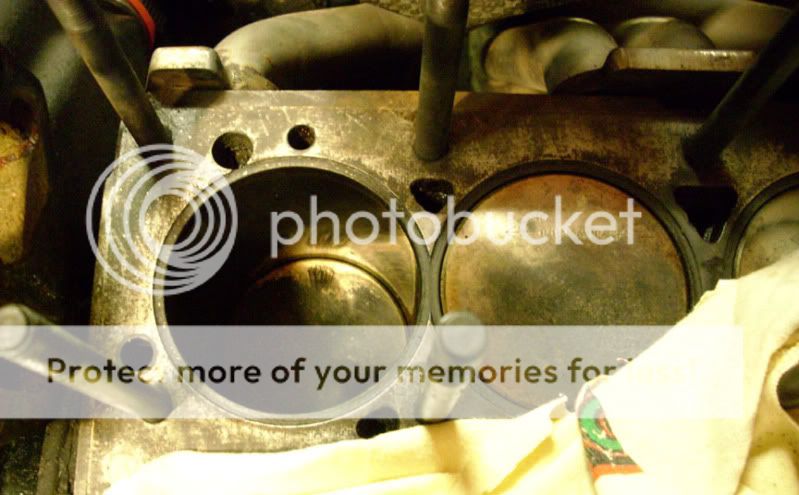

jlaird said:I would have valves removed, guides removed, boiled, leveled, new guides, valves ground, paint it preaty

Agree with all above that it may just be a durn head gasket.

The guy I bought my Monza from blew a gasket and had the head completely gone through and it smoked badly afterwards. A fresh 100% sealing head on old worn rings sometimes is a reciepe for trouble.

The only thing I would do other than have it cut, is do a quick light hand lap just to make sure the valves are still seating properly. Yeah, I know you can smack 'em in with a rubber hammer, but I like cleaned seats instead of a seat print.

Only way that I'd do the complete head is if I put new rings in ( in car) and all bearings (oil pump too).

Careful of the slippery slope or you might have some yard art for a while.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>