bigjones

Jedi Warrior

Offline

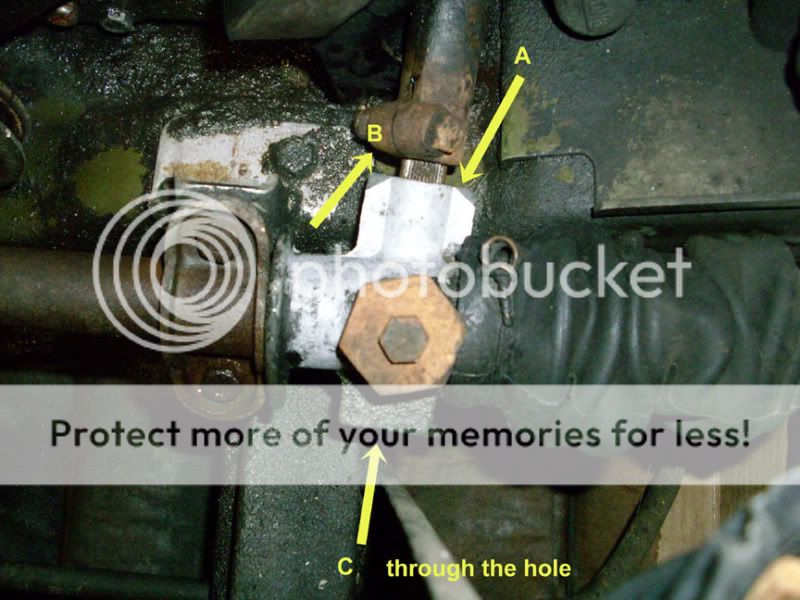

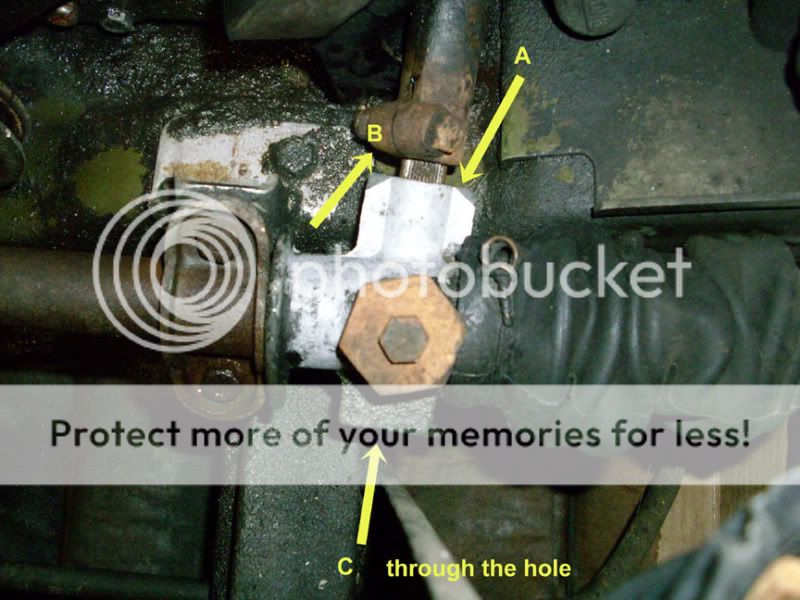

OK, I remove the pinch bolt.

Now, where do I tap with the drift and hammer? You are going to have to spell it out for me. Is it a,b or c. Left to my own devices I would put something up c and bang with a hammer.

Hey, while we are at it - I notice that Haynes refers to that small bolt on top of a larger, in the center of the photo, as a grease cap - am I supposed to remove that and squirt some grease down there?

No kidding, I've never done any thing with that. I took a hypodermic and shot some oil through the rubbers gaiters a while back but that is it.

Cheers!

Hmm, maybe not. Perhaps I would tap at location "b". But would the steering shaft move upward as desired?

Now, where do I tap with the drift and hammer? You are going to have to spell it out for me. Is it a,b or c. Left to my own devices I would put something up c and bang with a hammer.

Hey, while we are at it - I notice that Haynes refers to that small bolt on top of a larger, in the center of the photo, as a grease cap - am I supposed to remove that and squirt some grease down there?

No kidding, I've never done any thing with that. I took a hypodermic and shot some oil through the rubbers gaiters a while back but that is it.

Cheers!

Hmm, maybe not. Perhaps I would tap at location "b". But would the steering shaft move upward as desired?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>