-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A Transmission Service TR-2

- Thread starter Redoakboo

- Start date

Offline

Hey Red, you posted your question in the "Forum Help" forum - which is a place to ask questions about navigating this forum. Since your question relates to Triumph I am moving your thread to the Triumph forum. I will leave a "pointer" in the original forum that will expire in a week.

If you are reading this, you are now in the Triumph forum.

If you are reading this, you are now in the Triumph forum.

Thanks Basil,

Dick Vinal

It is leaking from both sides of the rod holes. I tried to fix new O rings on either side, didn't even slow down the leak. It doesn't seem to be coming out of either of the OD case seems? Now that I have sorted out the clutch slave cylinder problems, it is running. I have only driven in 1st & 2nd gear but, the rest to the transmission seems to be fine. I did put some gasket sealer on the solenoid plate, no dice?

Dick

Dick Vinal

Hi David,The only one I know of is in Alabama. He rebuilds them.

Where is it leaking from? The adaptor plate or the solenoid mounting plate?

David

It is leaking from both sides of the rod holes. I tried to fix new O rings on either side, didn't even slow down the leak. It doesn't seem to be coming out of either of the OD case seems? Now that I have sorted out the clutch slave cylinder problems, it is running. I have only driven in 1st & 2nd gear but, the rest to the transmission seems to be fine. I did put some gasket sealer on the solenoid plate, no dice?

Dick

CJD

Yoda

Offline

If you are installing the o rings as per the diagram in the OD manual, then the shaft will leak. The o ring position in the diagram is on the wrong side of the plate. I figured this out by replacing the o rings 3 times, and finally removed the solenoid plate to install them where they belong...on the inside of the box.

John,If you are installing the o rings as per the diagram in the OD manual, then the shaft will leak. The o ring position in the diagram is on the wrong side of the plate. I figured this out by replacing the o rings 3 times, and finally removed the solenoid plate to install them where they belong...on the inside of the box.

I did remove the plate and install them on the inside before I reinstalled the plate, with gasket material? I have the OD manual, pls tell me where it shows this o ring replacement? I may have done it wrong. How do you stop the leak on the other side of the case where the rod comes out?

Dick

David,

I have just finished installing the new O.D. harness and solenoid. I adjusted the bottom gap on the solenoid. I tried to test it; in 4th gear, O.D. switch on, no click or clack? Could the relay be bad? It is original and has been napping the last 30 years. Does it matter which relay I use, screw or spade terminals? $17 versus $209.

Dick

I have just finished installing the new O.D. harness and solenoid. I adjusted the bottom gap on the solenoid. I tried to test it; in 4th gear, O.D. switch on, no click or clack? Could the relay be bad? It is original and has been napping the last 30 years. Does it matter which relay I use, screw or spade terminals? $17 versus $209.

Dick

I did add two fuses at the relay. Is there a way to check whether the relay is bad?The inexpensive ones work fine as long as you don’t short across the terminals with a multi tester. I did it twice while in a fairly advanced yoga position. I’m glad I didn’t do that with a $200 relay.

Thanks, Dick

David, new question. I replaced the oil ring on the solenoid side of the O.D. ; took the housing off. That side no longer leaks. I have ordered a 6" 7/64" hard steel drill to try and get that #@&*( set pin out at the lever. I bent two hardened steel punches trying to knock it out. I tried to slip a extra "O" ring over the lever, still leaks.Thanks David,

It's DEAD! Ordered the cheaper one through Moss.

Dick

I tried to set the gap on the solenoid, thought I had it but, it is very hard to move the lever back and forth so, I'm sure it is not right? How easy should that lever move back and forth. Assuming I get the lever off and can install a new "O" ring, and it doesn't leak, I would like to make sure I have the solenoid adjusted right before I install the gear box cover.

Dick

That pin in the lever is most likely a tapered pin so you need to make sure you are driving it out the correct way. It can be hard to tell the small end from the big end but you must drive from the small end.

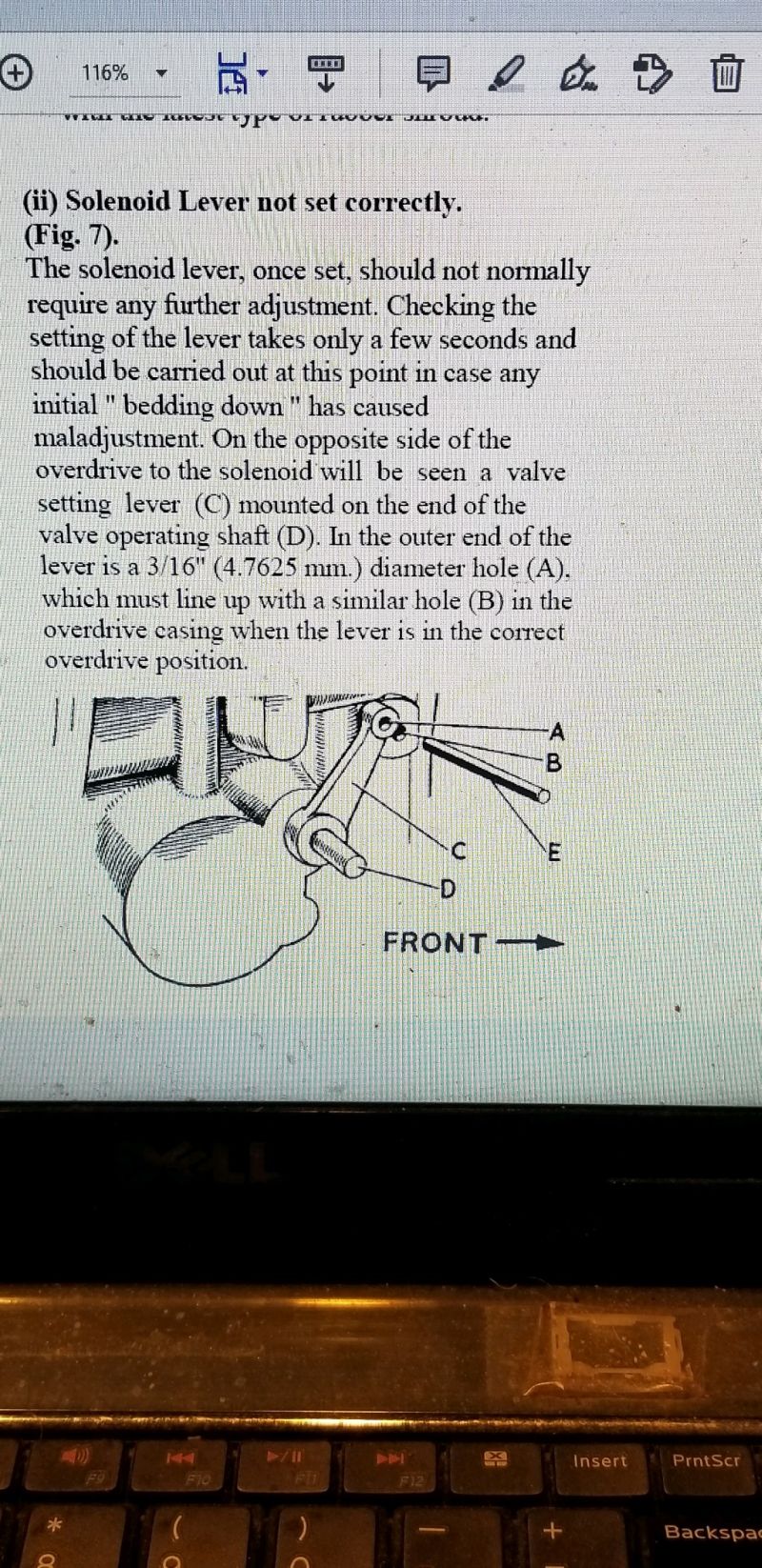

To move the lever I had to use a screwdriver to slightly open up the clamp on the shaft. I also went a fraction past the 3/16" hole alignment point.

I assume this is the lever that you are trying to remove the pin from?

David

To move the lever I had to use a screwdriver to slightly open up the clamp on the shaft. I also went a fraction past the 3/16" hole alignment point.

I assume this is the lever that you are trying to remove the pin from?

David

I assume I am trying to drive the tapered pin out correctly as the backside had a larger pin head and the front had a recessed hole where you could see the smaller end of the pin. I could not drive it out , through the hole in the lever and bent two hardened steel punches. I could not get my drill lined up with the hole, to close to the case. So, I have ordered 2 ea. 6" 7/64" hardened steel drills and will attempt to drill the pin out. This is nthe only place that is still leaking oil so have to change that "O" ring.David, Should the lever be in the position shown on your pic before it is actuated. And if I move the lever forward, should it stop lined up with the 3/16" hole?

Dick

CJD

Yoda

Offline

I assume you know that, as with the driver's side seal, the pax side also goes inside the box and not on the outside between the case and the lever? It goes inside the case between the case and the actuating cam. The drawings in the manual show the seal on the outside, which is not the correct location. I am not sure if the actuating rod can be removed from a fully assembled box to change that seal...but give it a try.

Also, the holes for the locator pins to set the solenoid will get you close, but after 60 years all the boxes are worn and will not likely operate correctly if you just put the pin in, set the solenoid and drive. It normally takes a tweak more open to get the boxes to engage and release positively. I set the solenoid by jacking the car and operating the OD with the wheels off the ground. Tweak the setting until you just get positive engagement, and that will give you a positive release too.

If you are force to drill the pin out, you will need a taper ream to repair the hole when you are done. If you bent the drifts, it likely means you are trying to tap a little off center...at an angle.

Also, the holes for the locator pins to set the solenoid will get you close, but after 60 years all the boxes are worn and will not likely operate correctly if you just put the pin in, set the solenoid and drive. It normally takes a tweak more open to get the boxes to engage and release positively. I set the solenoid by jacking the car and operating the OD with the wheels off the ground. Tweak the setting until you just get positive engagement, and that will give you a positive release too.

If you are force to drill the pin out, you will need a taper ream to repair the hole when you are done. If you bent the drifts, it likely means you are trying to tap a little off center...at an angle.

I have a 7/64" drill/tap combination and plan to replace the pin with a screw?I assume you know that, as with the driver's side seal, the pax side also goes inside the box and not on the outside between the case and the lever? It goes inside the case between the case and the actuating cam. The drawings in the manual show the seal on the outside, which is not the correct location. I am not sure if the actuating rod can be removed from a fully assembled box to change that seal...but give it a try.

Also, the holes for the locator pins to set the solenoid will get you close, but after 60 years all the boxes are worn and will not likely operate correctly if you just put the pin in, set the solenoid and drive. It normally takes a tweak more open to get the boxes to engage and release positively. I set the solenoid by jacking the car and operating the OD with the wheels off the ground. Tweak the setting until you just get positive engagement, and that will give you a positive release too.

If you are force to drill the pin out, you will need a taper ream to repair the hole when you are done. If you bent the drifts, it likely means you are trying to tap a little off center...at an angle.