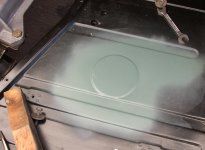

While looking at my rear brakes and waiting for my new drums, I was cleaning up some and getting ready to check the fluid in the shocks, when I looked up and saw the light or rather sunlight coming through the fender to body join. This car has been repainted, and the paint has cracked along the exterior joint. The inner fender well has been undercoated at some time also. Most of the fastners are covered with a couple showing where the undercoat has come away. The car was detailed prior to it's sale and they did a nice job of pressure washing the underside.

The question is,should I respray undercoating to cover the fastners and along the join area, thus sealing this from inside the fender well or ? My concern is that water(Pacific Northwest)will get in the join area from the top and cause rust. Should I use some kind of sealant on the exterior?

I am using this as a regular driver that is/will be returned to very nice condition. The car is relatively rust free although there is some in the rear deck where it joins the body tub. Same place as a previous string was discussed. I treated that with phosphoric acid stuff and spray painted it for now. I want to minumize further rusting until I pull the fenders off and treat it all properly. At least a year away.

Opinions! Thanks

The question is,should I respray undercoating to cover the fastners and along the join area, thus sealing this from inside the fender well or ? My concern is that water(Pacific Northwest)will get in the join area from the top and cause rust. Should I use some kind of sealant on the exterior?

I am using this as a regular driver that is/will be returned to very nice condition. The car is relatively rust free although there is some in the rear deck where it joins the body tub. Same place as a previous string was discussed. I treated that with phosphoric acid stuff and spray painted it for now. I want to minumize further rusting until I pull the fenders off and treat it all properly. At least a year away.

Opinions! Thanks

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.