Offline

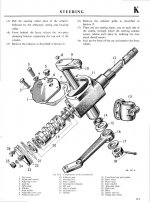

Steve - the pic is very helpful. The steering wheel was not removed for this job and what complicates assembly is its orientation relative to the worm and peg and thinking that it must be "centered". Will it self center? Thanks. GONZO

Yes the peg will self center in the worm. The thing that makes this mostly foolproof is that the steering arm fits in only one spot on the splines. So if you insert the peg at the far end of the worm, the steering arm will be angled accordingly. If the steering wheel hasn't been moved on the splines, it should align correctly.

When I messed up my worm gear, the steering felt a little off-center and had rough spots. This is because the rear bearing had slipped out of its race and was binding at an angle. With your box lid off, you should be able to see the rear bearing oscillate if it's not properly seated.

The other thing that happened to me was when I tried running the DW worm with a new DW peg the steering would bind and be sloppy at the same time. Wierdest thing. Turned out the DW peg was .005" greater in diameter than the stock peg and didn't seat all the way in the needle bearings, causing the peg arm to scrape on the box cover. Replaced it with the stock peg and all was well.

PS: in the pic above, the thin line is the sheet-metal carrier for the balls in the bearing. If this is oscillating or does not appear as it does in the photo above, the bearing may be unseated on the rear race.

Last edited:

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>