T

Tinster

Guest

Guest

Offline

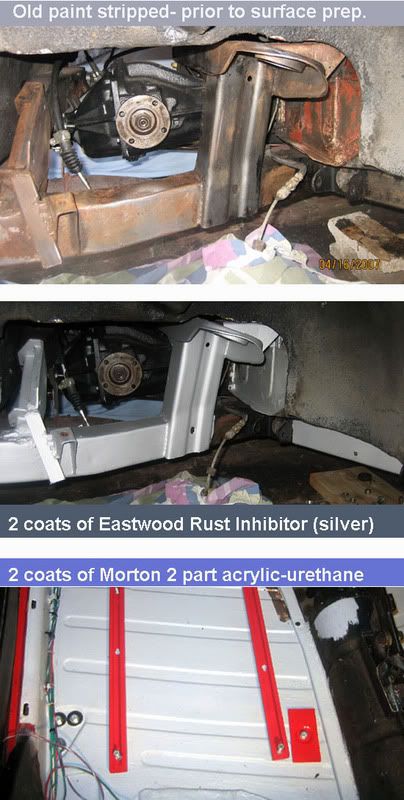

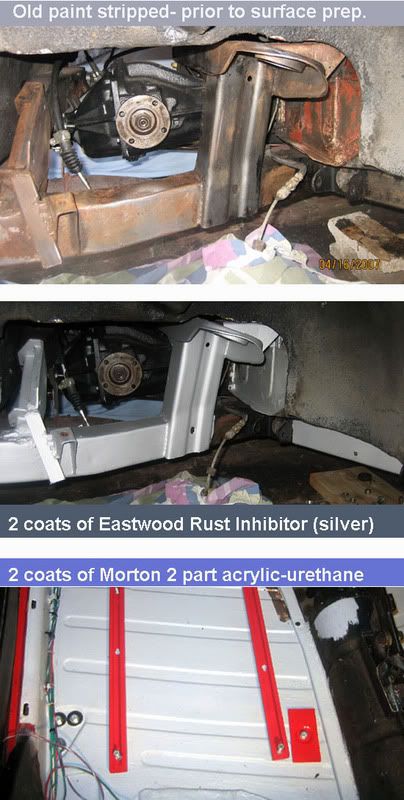

We all remember the mess TRBill got himself into

with his floor rust proof painting. Since I was about to

repair both floor pans right after Bill's nightmare, I did

a little research.

I'll relate my field findings and opinions on two rust paint

products I have now used.

a. Eastwood Rust Inhibitor- xylene based single component

1 quart silver color at $30.00 plus shipping

b. Morton Rust Inhibitor - 2 component acrylic/urethane

1 quart Grey) with 1 pint activator at $25. local.

I will do the write up after/below the photos that follow.

Both products have a very short useful brush life. Both

require small amounts poured or mixed from the parent cans.

With the Eastwood test area on my frame, I chemically

stripped the existing paint, scraped, degreaser cleaned,

then cleaned with xylol, dry sanded rust with 200 paper,

xylol, steel wool, xylol and then painted with Eastwood.

The Eastwood product is a very high xylene solvent based

paint that sets up into tac condition after maybe three

brush strokes. Fastest setting paint I have ever used.

This product requires decisive, long , brush strokes. Don't

even think about going back over it to make the brush lines

all nice and neat and parallel or fix runs and blobs. You'll

just make a mess. Dry to the touch in about 4 to 6 minutes.

I found using a 1.5" wide brush gave me opitmal results with

a decent finished look.

Because the Eastwood is a very high solvent product, it goes

on fairly thick but is pretty thin once the solvents

evaporate and the product has dried leaving behind the

solids. A minimum of two coats is a must, in MHO.

I tested the Eastwood resistance to brake fluid, solvent

based enamel paint and gasoline. All three "ate the paint.

With only 12 hours dry time, the Eastwood scratched easily.

The Eastwood Rust Inhibitor does NOT require burning the

rust or the deep cleaning I performed. It can go directly

over wire brushed rust. (Personally I think only a DPO would

not try to remove MOST of the rust)

I had to have my can of Eastwood barged shipped to PR and

it just arrived last Friday. Something to do with Homeland

Security and certain chemicals prohibited on aircraft.

While waiting for the barge to arrive I went to a local auto

paint shop.

Our local auto paint specialty shop does not carry the

Eastwood lines. My local shop recommended to me the

Morton 2 part acrylic/urethane rust product.

The Morton product is a non-solvent based paint that

requires mixing a catylyst to start off the chemical

reaction. A 4 parts urethane to one part catylyst ratio

is used.

The Morton product also requires use in small batches. It

has about a 20 minute useful brush life. It is possible to

go back over and make nice neat parallet brush lines and fix

drip and blobs. The acrylic/urethane also goes on thick but

retains it aplication thickness becaue it is chemical

reaction cured NOT solvent evaporation based. One coat on

my floor pans was probably good enough but I put on two

"just to be safe". Morton recomends burning the rust and

normal cleaning. I followed this procedure.

I also tested the cured Morton with brake fluid, solvent

based enamel paint and gasoline. There was no reaction or

softening of the acrylic/urethane. After 12 hours the Morton

acrylic/urethane was hard plastic I could not easily cratch.

I think The A/U will better resist road gravel and stones

kicked up from tires, etc.

Bottom line opinion:

I will continue to use the Eastwood product as a two coat

primer on my frame and engine compartment but I will overlay

it with the 2 part- chemically resistant- acrylic/urethane.

In the engine bay I will try to find red A/U top coat paint.

Several forum members are working in engine bays or on their

frames. I hope my observations help a bit.

best regards,

Dale in Sunny Puerto Rico

Yeah, Crypty is on jack stands...AGAIN!!

with his floor rust proof painting. Since I was about to

repair both floor pans right after Bill's nightmare, I did

a little research.

I'll relate my field findings and opinions on two rust paint

products I have now used.

a. Eastwood Rust Inhibitor- xylene based single component

1 quart silver color at $30.00 plus shipping

b. Morton Rust Inhibitor - 2 component acrylic/urethane

1 quart Grey) with 1 pint activator at $25. local.

I will do the write up after/below the photos that follow.

Both products have a very short useful brush life. Both

require small amounts poured or mixed from the parent cans.

With the Eastwood test area on my frame, I chemically

stripped the existing paint, scraped, degreaser cleaned,

then cleaned with xylol, dry sanded rust with 200 paper,

xylol, steel wool, xylol and then painted with Eastwood.

The Eastwood product is a very high xylene solvent based

paint that sets up into tac condition after maybe three

brush strokes. Fastest setting paint I have ever used.

This product requires decisive, long , brush strokes. Don't

even think about going back over it to make the brush lines

all nice and neat and parallel or fix runs and blobs. You'll

just make a mess. Dry to the touch in about 4 to 6 minutes.

I found using a 1.5" wide brush gave me opitmal results with

a decent finished look.

Because the Eastwood is a very high solvent product, it goes

on fairly thick but is pretty thin once the solvents

evaporate and the product has dried leaving behind the

solids. A minimum of two coats is a must, in MHO.

I tested the Eastwood resistance to brake fluid, solvent

based enamel paint and gasoline. All three "ate the paint.

With only 12 hours dry time, the Eastwood scratched easily.

The Eastwood Rust Inhibitor does NOT require burning the

rust or the deep cleaning I performed. It can go directly

over wire brushed rust. (Personally I think only a DPO would

not try to remove MOST of the rust)

I had to have my can of Eastwood barged shipped to PR and

it just arrived last Friday. Something to do with Homeland

Security and certain chemicals prohibited on aircraft.

While waiting for the barge to arrive I went to a local auto

paint shop.

Our local auto paint specialty shop does not carry the

Eastwood lines. My local shop recommended to me the

Morton 2 part acrylic/urethane rust product.

The Morton product is a non-solvent based paint that

requires mixing a catylyst to start off the chemical

reaction. A 4 parts urethane to one part catylyst ratio

is used.

The Morton product also requires use in small batches. It

has about a 20 minute useful brush life. It is possible to

go back over and make nice neat parallet brush lines and fix

drip and blobs. The acrylic/urethane also goes on thick but

retains it aplication thickness becaue it is chemical

reaction cured NOT solvent evaporation based. One coat on

my floor pans was probably good enough but I put on two

"just to be safe". Morton recomends burning the rust and

normal cleaning. I followed this procedure.

I also tested the cured Morton with brake fluid, solvent

based enamel paint and gasoline. There was no reaction or

softening of the acrylic/urethane. After 12 hours the Morton

acrylic/urethane was hard plastic I could not easily cratch.

I think The A/U will better resist road gravel and stones

kicked up from tires, etc.

Bottom line opinion:

I will continue to use the Eastwood product as a two coat

primer on my frame and engine compartment but I will overlay

it with the 2 part- chemically resistant- acrylic/urethane.

In the engine bay I will try to find red A/U top coat paint.

Several forum members are working in engine bays or on their

frames. I hope my observations help a bit.

best regards,

Dale in Sunny Puerto Rico

Yeah, Crypty is on jack stands...AGAIN!!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>