T

Tinster

Guest

Guest

Offline

Well, I read Bentley Blue, looked at all the great reference photos, pondered the great advice and got out wrenches and camera this morning. I think it was Randal who cautioned me to back off the 6 bolts poca a poco - thanks for the tip. Paul, I think the oil feed hole looked very open.

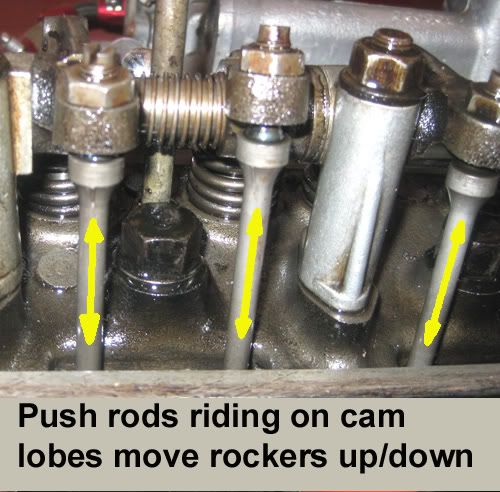

Here are a few photos for the non-mechanic guys like me who might never have seen what is actually under that valve cover in your car. Pretty interesting really. Even better with the engine running. The look like tiny oil well pumps!

But I might have screwed up (I hope not too badly) I pulled out 2 push rods out of curiosity. Is this a majot screw up?

My project today was to remove the valve rocker arms assembly.

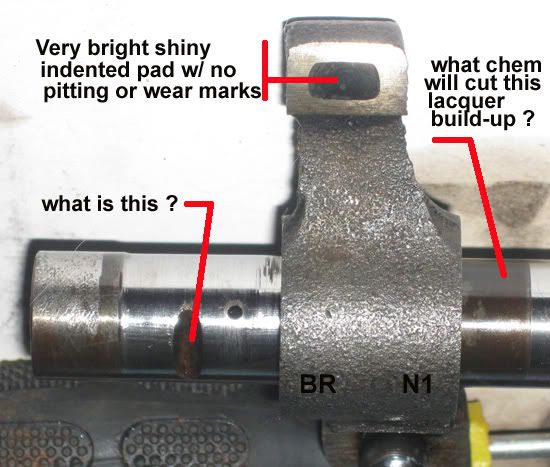

I am using a "parts board" to lable every part in proper orientation. If anyone spots anything dreadful please pipe up.

This is a bare bones project from a $$$ available viewpoint.

Photo above is after the rocker assembly has been removed.

edit: add text.

Here are a few photos for the non-mechanic guys like me who might never have seen what is actually under that valve cover in your car. Pretty interesting really. Even better with the engine running. The look like tiny oil well pumps!

But I might have screwed up (I hope not too badly) I pulled out 2 push rods out of curiosity. Is this a majot screw up?

My project today was to remove the valve rocker arms assembly.

I am using a "parts board" to lable every part in proper orientation. If anyone spots anything dreadful please pipe up.

This is a bare bones project from a $$$ available viewpoint.

Photo above is after the rocker assembly has been removed.

edit: add text.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>