OP

Tinster

Guest

Guest

Offline

Thanks Yisrael!

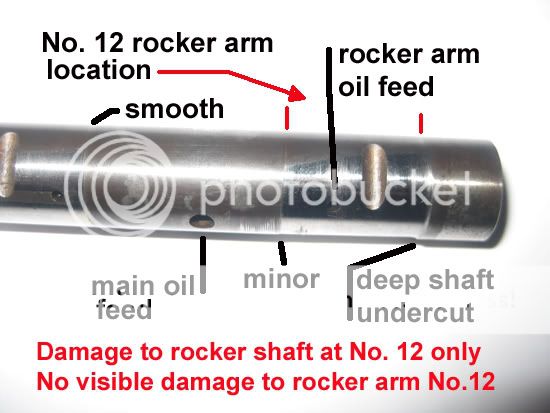

I was wondering that same thing, now that I've been eyeball

to eyeball with this contraption form many hours. No. 12

rocker has a ridge but No.1 is very smooth and also dry.

I've already figured a new shaft is required.

Removing the darned pedestals is givine me fits. Even after

soaking all night. I spent a total of 4 hours to remove one of the 4 intermediate pedestals. Is there a trick?

Thanks all !

I was wondering that same thing, now that I've been eyeball

to eyeball with this contraption form many hours. No. 12

rocker has a ridge but No.1 is very smooth and also dry.

I've already figured a new shaft is required.

Removing the darned pedestals is givine me fits. Even after

soaking all night. I spent a total of 4 hours to remove one of the 4 intermediate pedestals. Is there a trick?

Thanks all !

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>