I'm Back! Anybody miss me?

So...continuing on with the build....

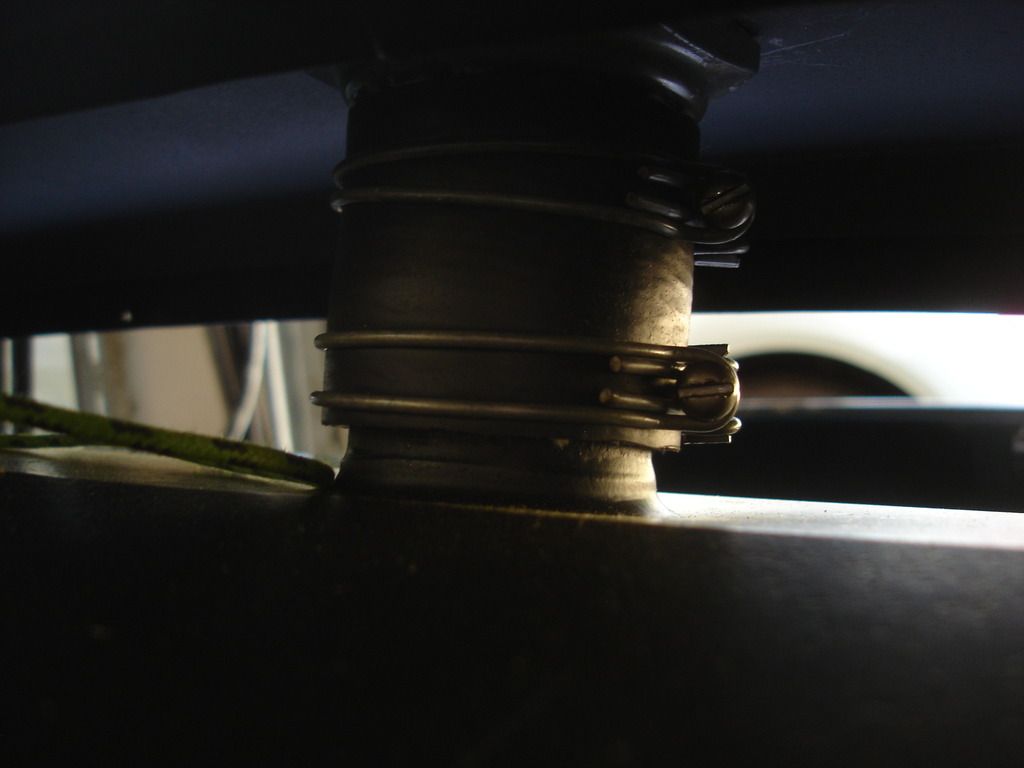

This is the battery drain hose going in place.

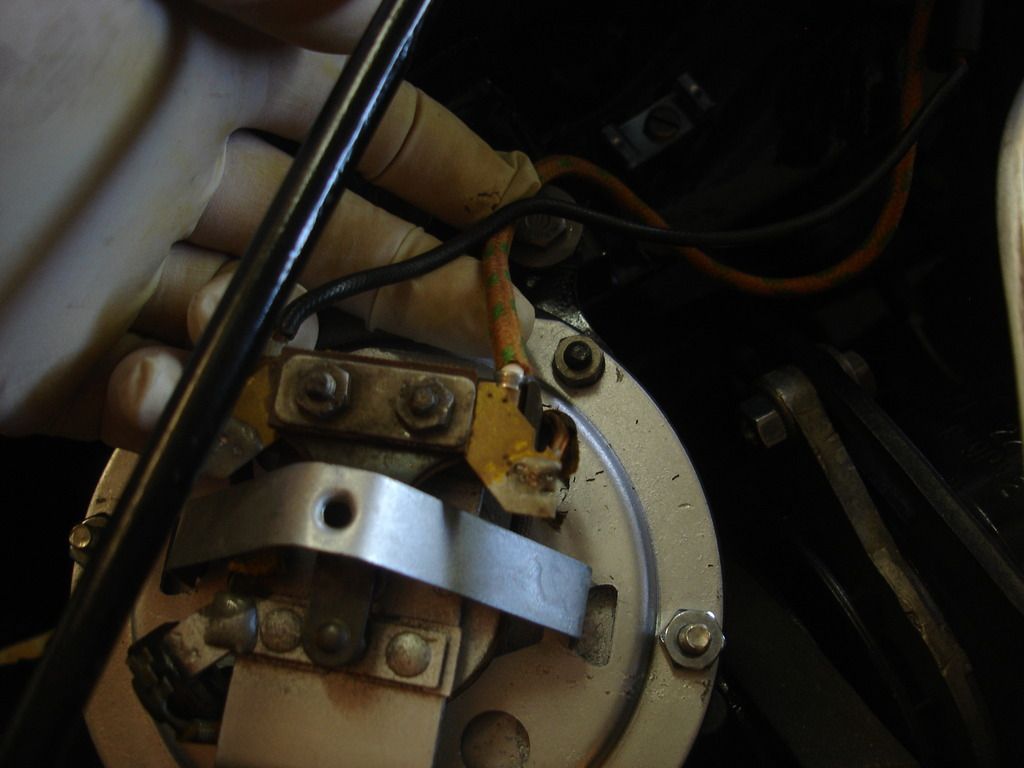

Battery ground cable. The judging guide says it should be round. The connector is NOT correct, but the guide also says not to deduct for this connector, since the original was finnicky at best.

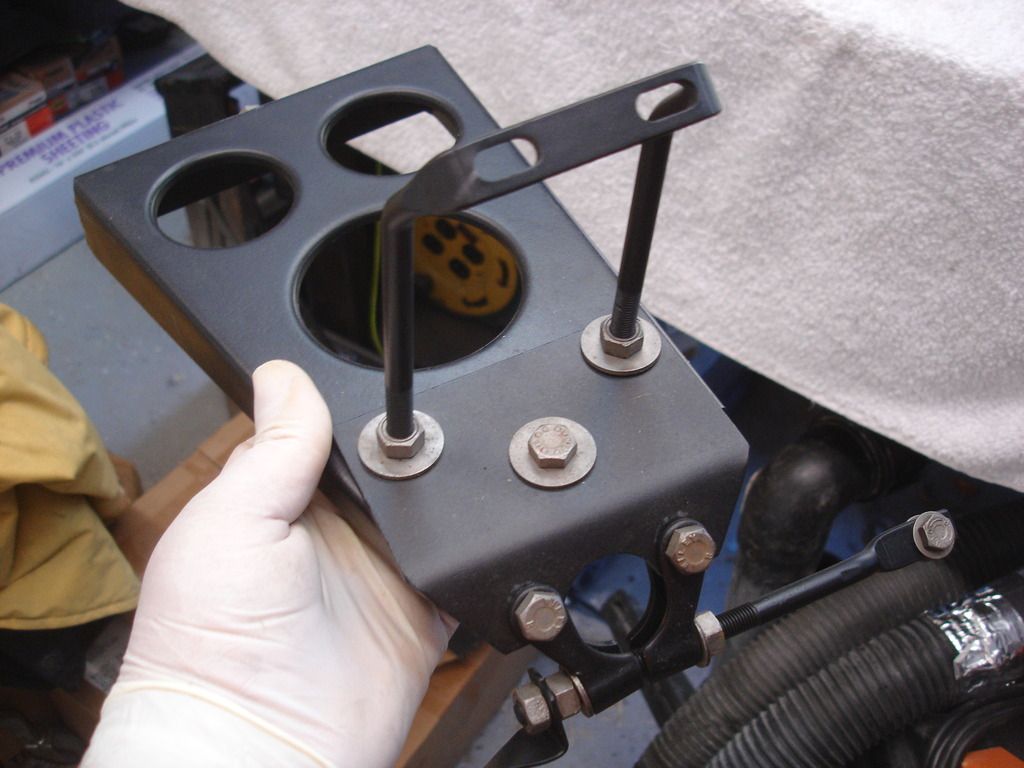

Not a good pic, but these are the 3 plugs that go over the right side brake blanking plate. On a RHD car this is where the steering column support would anchor.

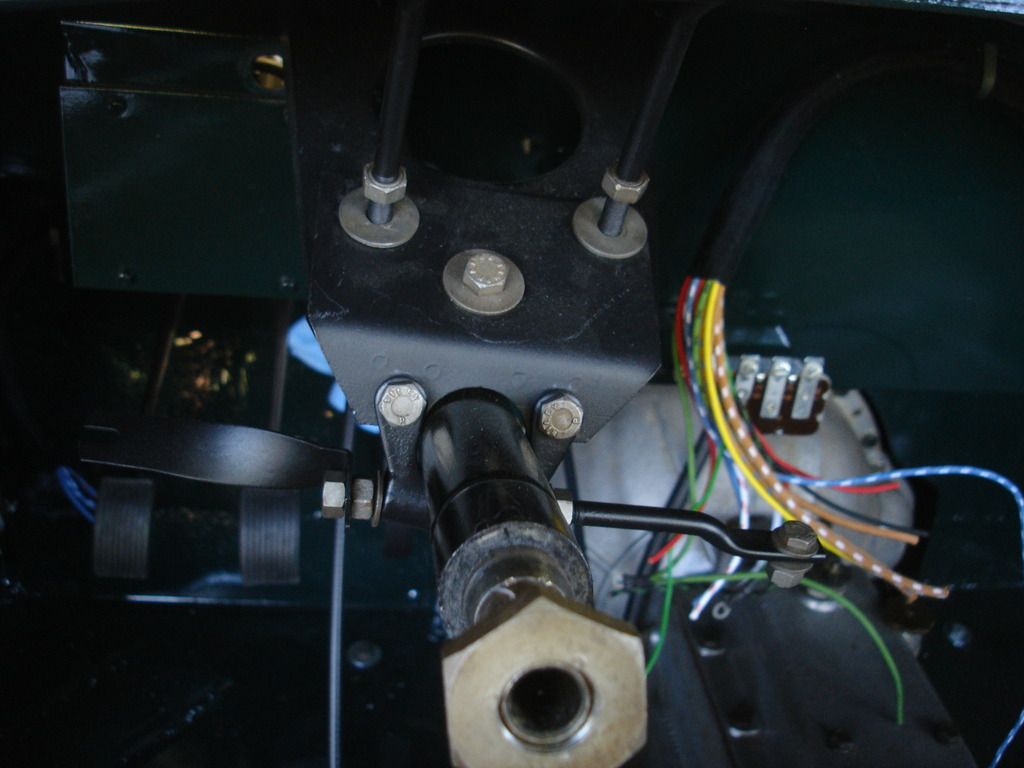

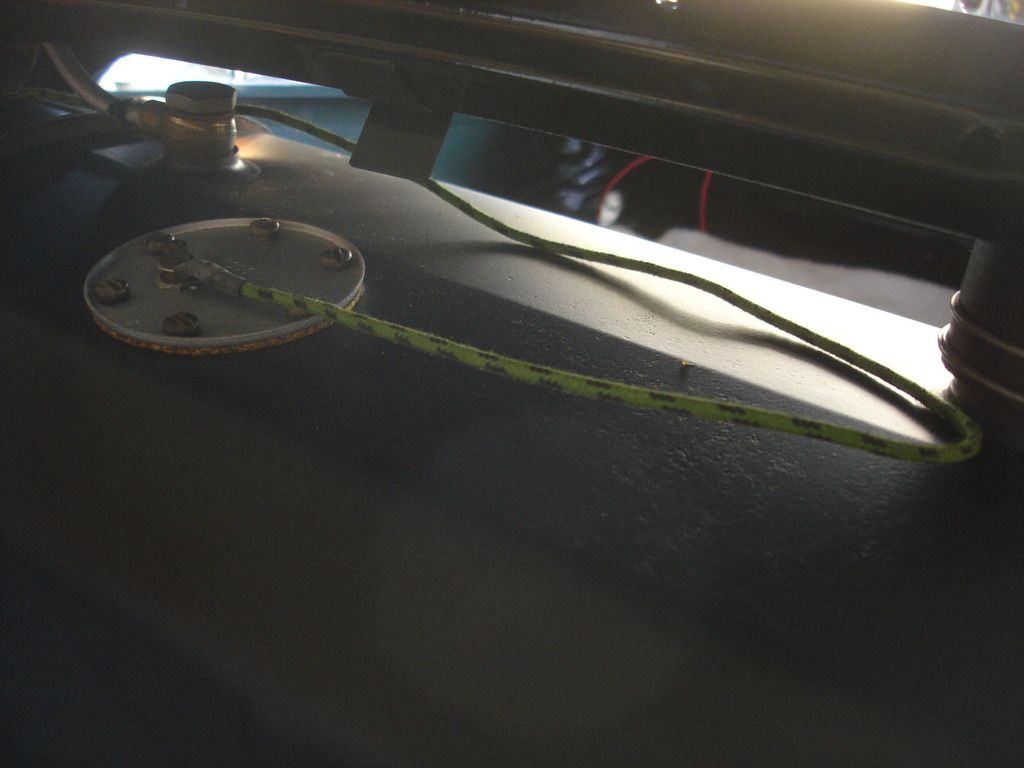

Fuel tank took 2 full days to go in. I will spare the details, but the problem is getting the filler neck to center in the body hole. Either my boot floor is different, or the Ebay tank was different. I finally fixed the problem with strategically placed felt strips under the tank. This is a pic of the tank sending wire attached.

The Moss wiring harness even has a little protector where the wire turns the corner over the top of the tank. I did have to use a tie to keep the wire so the protector is in the right place.

Floor plugs for the jack holes. These are not correct, but as far as I can tell, the "correct" metal plugs for the TR2 are NLA. They are easily replaced if the correct ever become available.

Now it's time to align the engine with the radiator. We'll start with a floor jack under the engine, using a large wood block to spread the load.

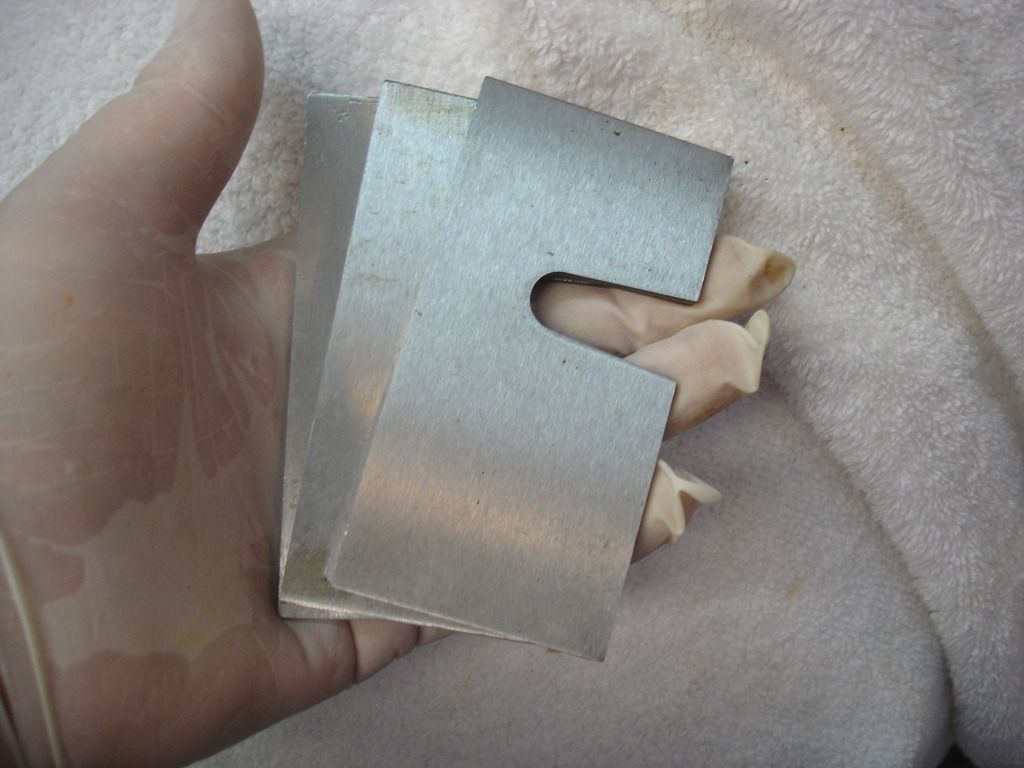

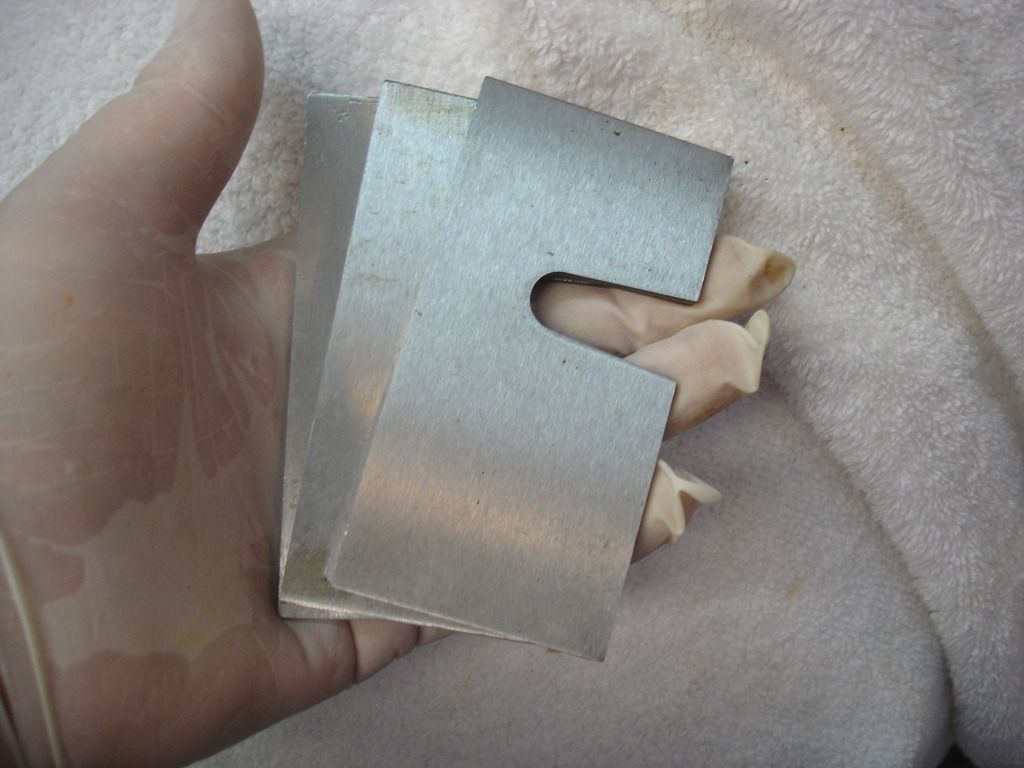

These are the shims that go between the engine front plate and the rubber mounts. (Thanks Tush!)

This is the original crank installed. The key is to raise the engine and install shims left, right, or both to align the crank in the radiator hole.

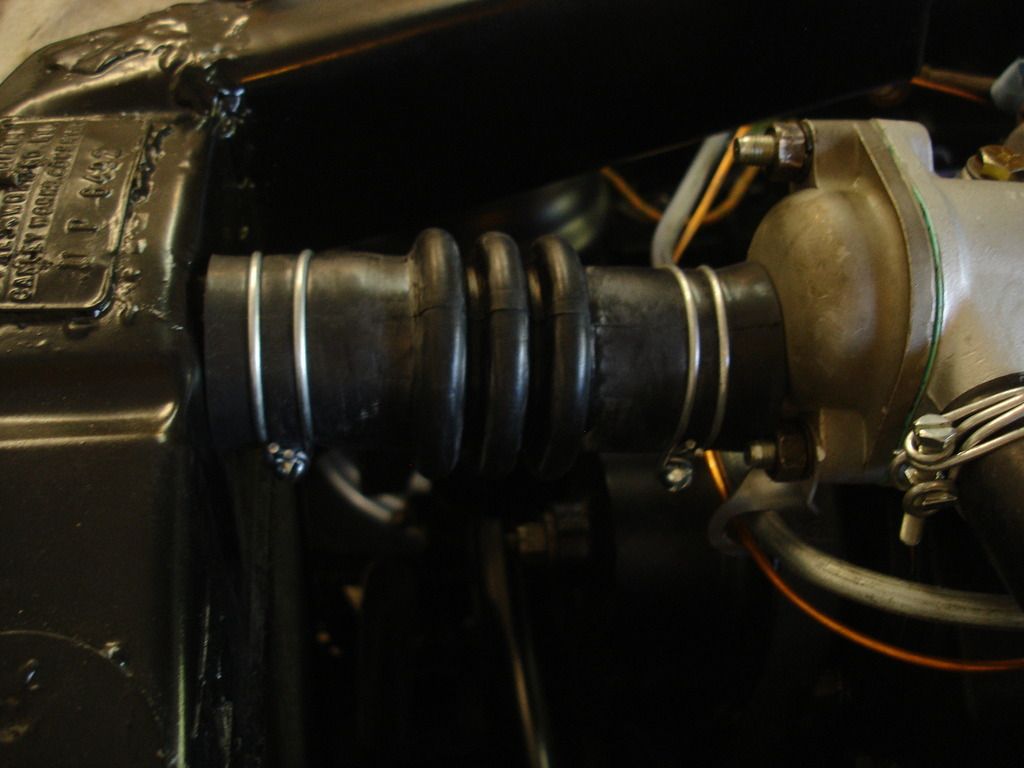

Here is a shot of the crank engaging the crank extension...dead center!

Dark, but these are a pic of the right side shim pack to do it.

Oh...forgot to show the tank installed...

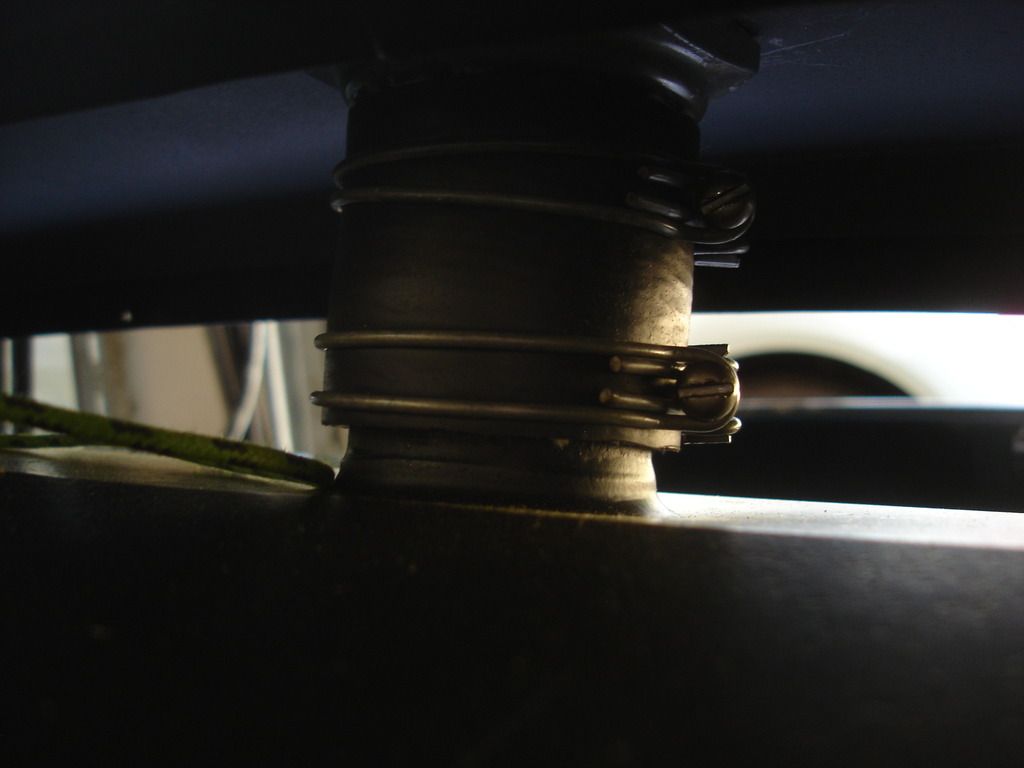

This is the PITA in the tank installation. The neck piece is a bear to install on top of the tank filler neck, AND it must absolutely center in the body opening. If not centered, it will distort your body work around the filler cap.

Once the extension and hose are all aligned, with the tank securely strapped down...then you can tighten the clamps to hold the extension in place.

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>