tri_carb_healey

Senior Member

Offline

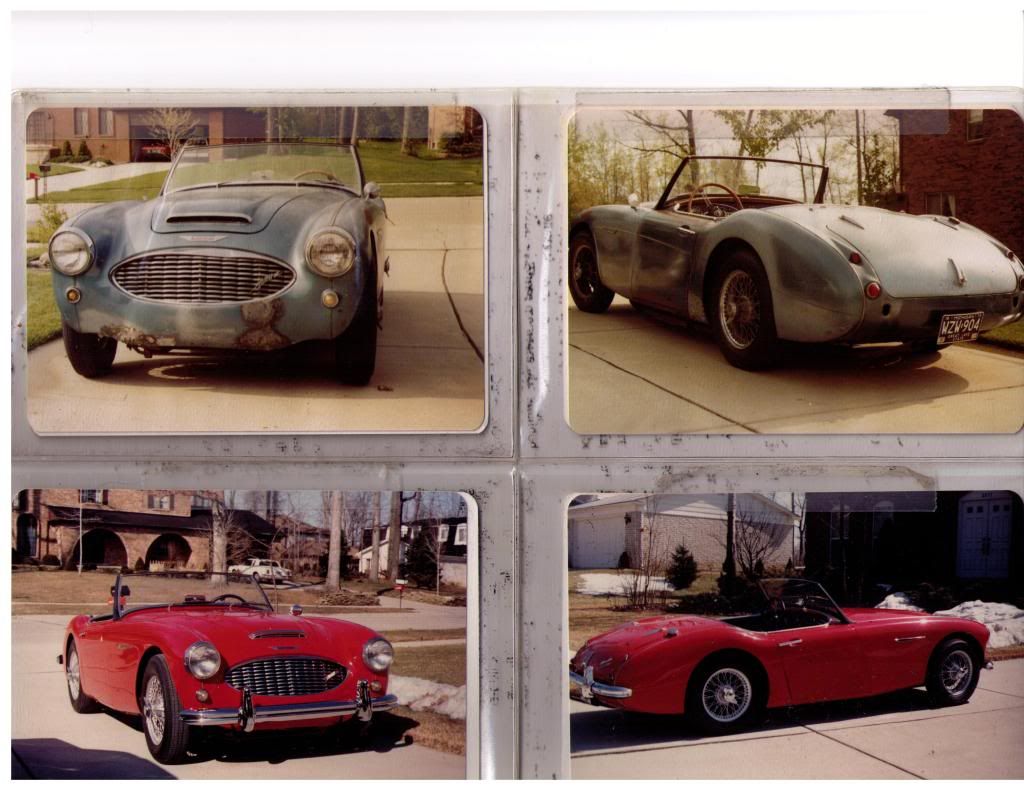

heare some photos i took trying to shaw some of the flaws, any tips about anything would be nice

this fender just has light, light surface rust, how would i prep this and the other spots for a body shop?

here are the doors

what do you guys think about these shut lines?

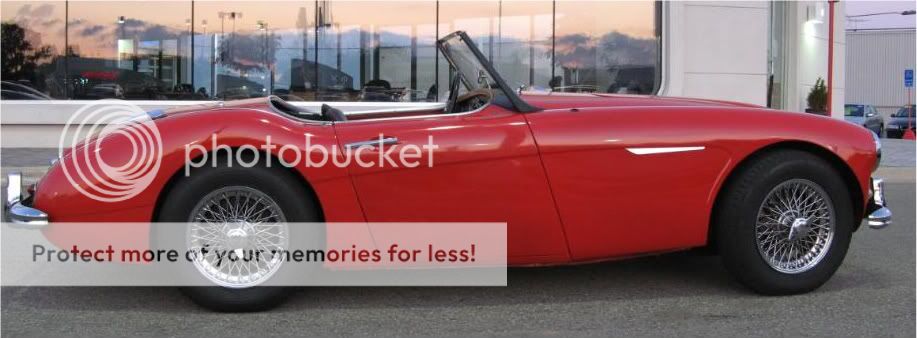

and just because, heres my tri carbs

how much would this work cost to get done?

this fender just has light, light surface rust, how would i prep this and the other spots for a body shop?

here are the doors

what do you guys think about these shut lines?

and just because, heres my tri carbs

how much would this work cost to get done?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>