I could share my shade-tree hoist method (although I didn't have a stand either); but maybe I'd better not

Definitely on the risky side!

Even with a purpose-made valve spring compressor, I find it helps to loosen the keepers first. Lay a big nut (or equivalent) on the bench, then set the head down so the valve head in question is on top of the nut. Then set a short length of pipe on top of the retainer, and give it a sharp rap with a BFH. Usually one is all it takes, but you can tap it a second time to feel that they came loose.

The tool I prefer for removing them is a length of heavy flat iron (originally sold as a stake for retaining concrete forms at the local "big box" store), with one end slotted to fit under a rocker shaft nut and a strategically located hole big enough to remove the keepers through. Sorry, don't have a photo, tho I might be able to take one tomorrow if my description isn't clear.

The washers I mentioned are Moss 324-825. You'll need 10 of them.

New parts are frequently problematic, so I lean towards not replacing anything that doesn't need to be replaced (ain't broke means don't fix it). So for example I have almost always reused all of the clutch components. The stock clutch is huge compared to the engine output, friction plate seems to last forever (at least for me). The only time I had a subsequent problem, it turned out I had installed the wrong TOB; the one I took out was still laying on the bench!

If cost is an issue and you have some retirement money to invest, you might want to look into TRF's Customer Investment Program. You make a personal loan to Charles (ISTR $5K is the minimum) and get back a pretty good rate of interest each month, plus 30% off list price on almost all parts. After 5 years, you get your original investment back.

Definitely pull the liners out, even if you plan to reuse them. The amount of crud that accumulates, especially behind #4, is just incredible.

Timing sprockets are Moss 838-000 and 837-040

If you are changing valves & guides anyway, you might want to consider using the TR4A exhaust valves with the 5/16" stem and conversion guides.

Replacing the wrist pin bushings is a machine shop job, and usually not necessary in my experience. I also don't bother to have the rods checked for straightness, unless the engine blew up or there are signs they aren't straight (like uneven wear on rod bearings or wear on the fore/aft side of the pistons).

Usually a good idea to chase the threads on the manifold studs IMO. You might want to pick up a set of rethreading dies.

https://www.mcmaster.com/?m=true#2667a11/=13zm5wg

I also find it helps to add a thick flat washer (aka setup washer) to the outermost exhaust manifold studs (the ones without bridge pieces).

Oh yeah, also good to replace the studs & nuts at the bottom of the exhaust manifold, with plenty of anti-seize on the threads.

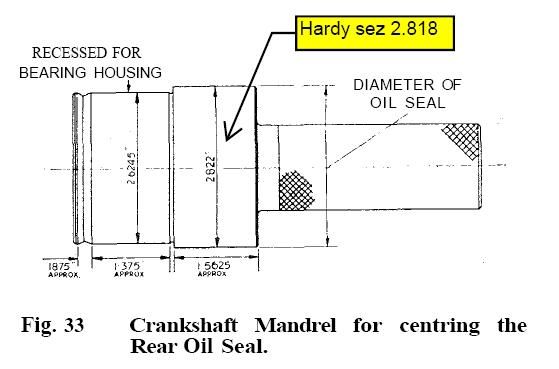

I don't see a rear main seal on your list. (thot you mentioned it before, tho). I definitely prefer the "Mad Marx" viton seal, but it isn't available through Moss. If you prefer to use the stock type seal, you should still get the corrected mandrel for setting it (the one Moss sells was still wrong, last I heard). The dimensions in the manual are wrong

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>