-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lower wishbone bush replacement.

- Thread starter Jeepster

- Start date

Keoke

Great Pumpkin

Offline

Gotta ask ... If you cut the end off the bolts, how do you drive the bolt out of the bush? That's where they get stuck. I've used a crowbar to lever them out; yes, you have to re-flatten the big end of the bolts/pins before reinstalling.

Get two sockets:

One with the inside diameter just a wee bit larger than the outside diameter of the bushing.

The other one with an outside diameter same as the busing.

Set the wishbone on top of # ! and Place #2 on top of the bushing drive bushing out use Led hammer OK.

This works on rear spring bushes too----

Bob's method is good too.

Healey Nut

Luke Skywalker

Offline

Get two sockets:

One with the inside diameter just a wee bit larger than the outside diameter of the bushing.

The other one with an outside diameter of the busing.

Set the wishbone on top of # ! and Place @2 on top of the bushing drive bushing out use Led hammer OK.

This works on rear spring bushes too----

tried this, didnt work so I resorted to the gas axe . Set up my portable workbench outside and heated the wishbone till the rubber caught fire and the remains of the bolts and bushings fell out .

Keoke

Great Pumpkin

Offline

tried this, didnt work so I resorted to the gas axe . Set up my portable workbench outside and heated the wishbone till the rubber caught fire and the remains of the bolts and bushings fell out .

Well What CHU expect in all that COLD.---LOL

Bob_Spidell

Yoda

Offline

Just be sure to have a good look at the suspension brackets at your annual inspection; an 'upgrade' on one part of a suspension usually puts a greater load on other parts (FWIW, I have poly bushes top and bottom).

Offline

Tom's sells flexible poly bushings without center tubes, which he says have lasted 20 years on his car. In their shop, they've started drilling the pins and fitting grease fittings.

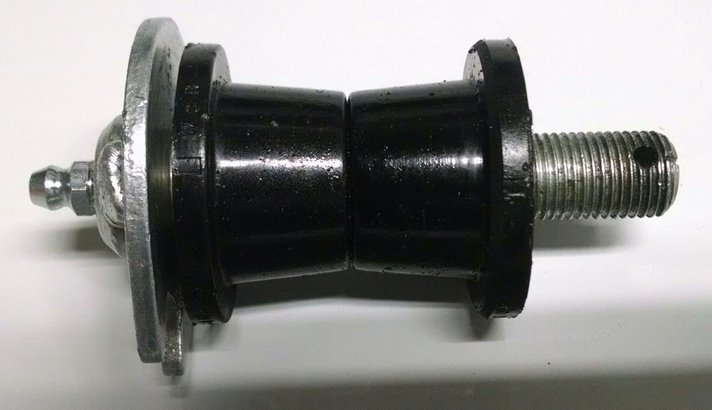

I performed a proof-of-concept on a spare pin. Lengthwise drill - 7/64", cross drills - 3/32":

I performed a proof-of-concept on a spare pin. Lengthwise drill - 7/64", cross drills - 3/32":

Last edited:

Bob_Spidell

Yoda

Offline

That's a great idea. Wish I had these last time I did this onerous job.

Offline

Is there, or would it benefit from, a grease track on the bush ID?

Danny

I don't think it's necessary as the extreme hydraulic pressure from the grease gun (combined with flexible bush material) forces the grease around the inside bore of the bushes. It certainly did that on the bench.

bob hughes

Luke Skywalker

Offline

A bit OTT

I just put copper grease on mine before reassembling.

Bob

I just put copper grease on mine before reassembling.

Bob

Randy Forbes

Yoda

Offline

The next person to take mine apart will find the same thing (Kopr-Shield by Thomas & Betts).A bit OTT

I just put copper grease on mine before reassembling.

Bob

Offline

Like the designers in Detroit used to say: "Too much is just enough."

Addendum: when one goes to all the trouble to remove the sqeaking bushings from the lower suspension arms, if one has the tools (drill press, v-block, 1/4-28 tap, grease fittings) not that much additional effort is involved to add grease fittings and ensure not having to disassemble the bushings ever again.

Addendum: when one goes to all the trouble to remove the sqeaking bushings from the lower suspension arms, if one has the tools (drill press, v-block, 1/4-28 tap, grease fittings) not that much additional effort is involved to add grease fittings and ensure not having to disassemble the bushings ever again.

Last edited: