Offline

That's very impressive, Jon. I can do a lot of work on my cars by myself, but there's a lot of stuff, like this, that are way beyond me. Good for you for trying it and making it work.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Thanks Rick. I'd still be a square 1 if not for the drawing and contact you sent me. ...

Jon,

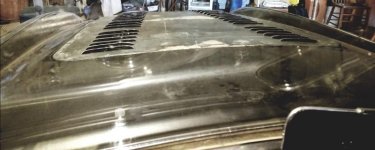

Bob, I hate to contradict but, if the owner is telling the truth, a BJ8 was ordered with a louvered bonnet and delivered from the factory in England with it. He later toured England and Ireland before shipping it home. He had an accident during the tour and the bonnet was replaced but he showed me a picture of the car in front of the Factory. I admit it was the only BJ8 that I know of delivered with louvers but, who knows.

Ray(64BJ8P1)

Thank you very much for taking the time to photo and explain your process. One question have I, do the louvers ever allow a mist of coolant or oil to fog the windscreen?