bigjones

Jedi Warrior

Offline

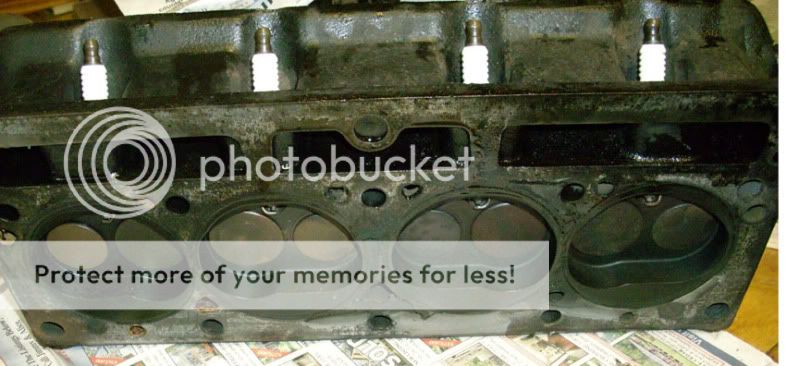

Hi folks,

Short story: A friend of a friend has come down to visit. The car (1500 Midget) overheated on the freeway last night.

This morning we went to take a look - car would not start and there was dirty oil in the coolant overflow bottle.

Had it towed back to my place where I've just done some compression tests (psi) - cold engine - (has a Weber carb so didn't know how to open the throttle):

#1: 142

#2: 100

#3: 79

#4: 112

and #1 again: 136

(all plugs removed)

I've a home-made leak-down tester someplace that I can use to analyze some more but what do you think so far?

Ideas, suggestions, most welcome as always.

Cheers!

Short story: A friend of a friend has come down to visit. The car (1500 Midget) overheated on the freeway last night.

This morning we went to take a look - car would not start and there was dirty oil in the coolant overflow bottle.

Had it towed back to my place where I've just done some compression tests (psi) - cold engine - (has a Weber carb so didn't know how to open the throttle):

#1: 142

#2: 100

#3: 79

#4: 112

and #1 again: 136

(all plugs removed)

I've a home-made leak-down tester someplace that I can use to analyze some more but what do you think so far?

Ideas, suggestions, most welcome as always.

Cheers!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>