CJD

Yoda

Offline

Hey David,

Thanks...I've replaced 7 circuit boards so far. Each one that gets replaced leads to another fried part. But it's gradually getting repaired.

I used to blast on the driveway, and between every tank I'd sweep the sand, strain it, and reuse it. It was a whole lotta work, and no matter how much I strained, I'd get frequent clogged nozzles that slowed me down. I finally grew tired of sweeping the drive, and moved to the back yard. The sand gets blasted once and then just fills in the lows in the yard. Costs about $30 per day more to blast that way...I decided that was a fair price to save wear and tear on my back.

I've been using "Black Diamond" sand from Norther Tool.

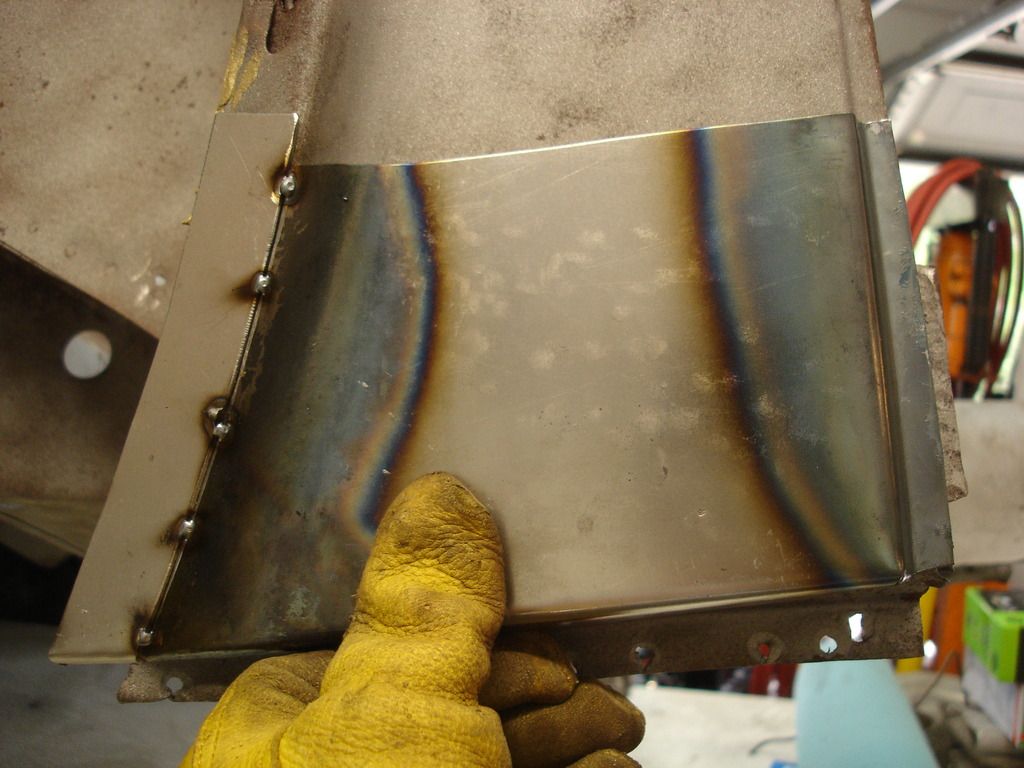

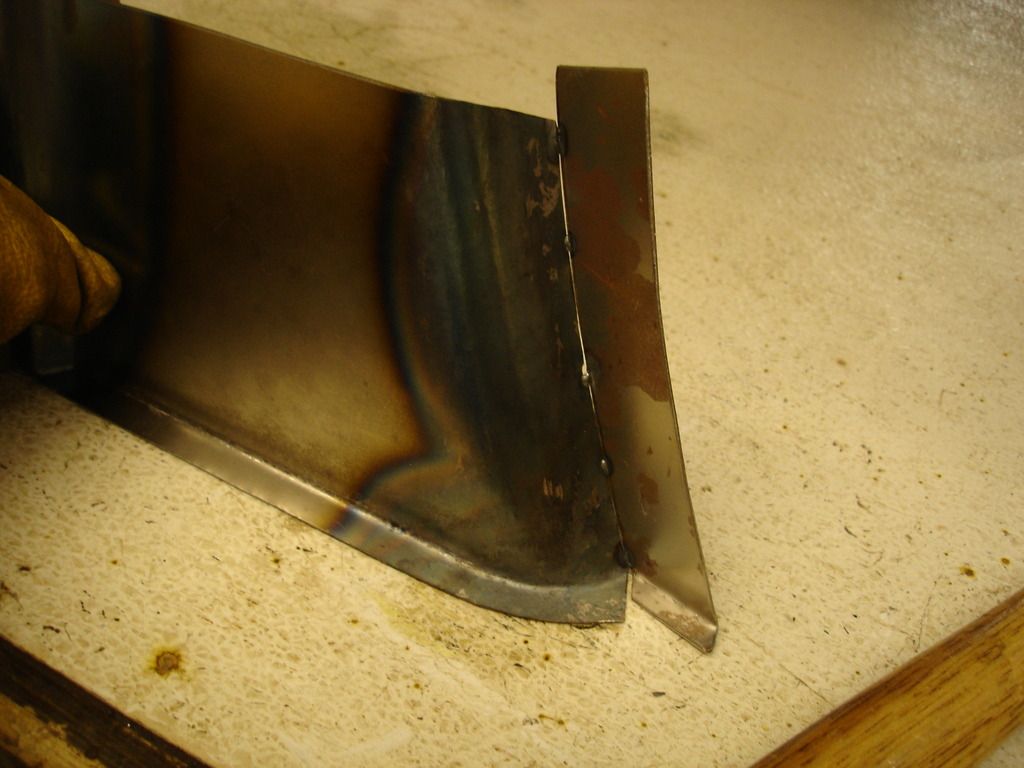

I think my round cornered patching goes back to my engineering classes. Sharp corners in engineering is always a no-no. They cause "stress risers". But, for what we are doing with body work, I don't think it really matters.

Thanks...I've replaced 7 circuit boards so far. Each one that gets replaced leads to another fried part. But it's gradually getting repaired.

I used to blast on the driveway, and between every tank I'd sweep the sand, strain it, and reuse it. It was a whole lotta work, and no matter how much I strained, I'd get frequent clogged nozzles that slowed me down. I finally grew tired of sweeping the drive, and moved to the back yard. The sand gets blasted once and then just fills in the lows in the yard. Costs about $30 per day more to blast that way...I decided that was a fair price to save wear and tear on my back.

I've been using "Black Diamond" sand from Norther Tool.

I think my round cornered patching goes back to my engineering classes. Sharp corners in engineering is always a no-no. They cause "stress risers". But, for what we are doing with body work, I don't think it really matters.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>