Strike two. The first strike was the trying to get the space needed for the balancer to get started. The second, failed getting the balancer seated today completely. Thankfully, I had my gear puller near by and we were able to pull off, but have to say, this is a TIGHT TIGHT! We boiled the balancer in water per instructions, used a jack pipe handle against a piece of 2x4 that rested flat on the balancer. Pummeled the pipe till the wood had 1" holes and couldnt get it more than half way seated. What took the longest was making sure the keyway was lined up, that was probably just 2 min, but enough to kill us.

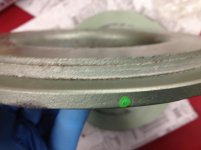

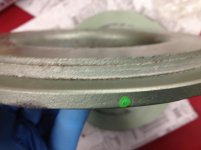

I think for sure I had the power was enough behind the blows, but the give in the wood block took away the inertia I needed to send it home im thinking. Below is a witness mark of how far it made it on, only half way.

Tomorrow, im going to grind down the socket to fit into the balancer like Randys, or send to him. Ill also build a pipe or box tube with a flat end to hit with a sledge! Its on like a prize fight now!

Also, some pics of the old damper. Please please tell me it was bad, that the preventive maint was for sure saving me from a certain catostrophic event and this was worth my time. Like, a story that was certain to unfold, like that the car at high RMP would have sent the starter nut into space and taken out an orbiting satellite, landing on my lawn!. Please tell me this!!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>