bigjones

Jedi Warrior

Offline

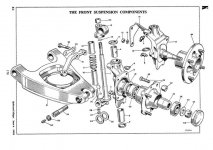

Hi folks,

I went to tighten that castellated nut but 46 ft lbs seems an awful lot.

I tightened it by hand - the disc could be spun with a certain amount of drag that felt about right. (Just to give you an idea of my "hand tight" - I could turn the nut further from hand-tight with the torque wrench set at 10 ft ilbs)

Using the torque wrench, without even reaching 46 ft lbs, the disc could not be spun - it is locked solid.

I realise that the nut should be backed off (if necessary) to get the slot in the spindle lined up with a castellation but even so.

I must be doing something wrong here.

Any ideas?

Adrian

1500 Midget

I went to tighten that castellated nut but 46 ft lbs seems an awful lot.

I tightened it by hand - the disc could be spun with a certain amount of drag that felt about right. (Just to give you an idea of my "hand tight" - I could turn the nut further from hand-tight with the torque wrench set at 10 ft ilbs)

Using the torque wrench, without even reaching 46 ft lbs, the disc could not be spun - it is locked solid.

I realise that the nut should be backed off (if necessary) to get the slot in the spindle lined up with a castellation but even so.

I must be doing something wrong here.

Any ideas?

Adrian

1500 Midget

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>