Re: Trunnion bushes - Help!

Thanks for the help - the new bushes are installed. And all before midnight.

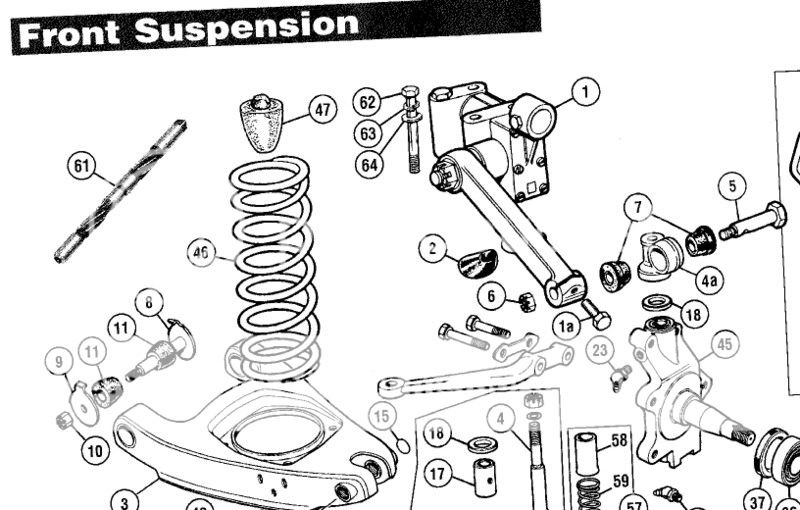

I do have a couple of concerns though, regarding that castellated nut, that maybe you could comment on:

1. The size of the cotterpin securing the nut is awfully thin. I tried it out on the bench and picked the thickest one that would fit but still it is worrying to me that it is not what you would call stout.

2. In order for the cotterpin to actually go through the castellations of the nut, I had to use a (grade 8) washer under the nut, otherwise the cotterpin would be above the nut.

3. Haynes says the torque on the nut should be 40 ft.lbs.

But then I had to back it off (to the stage where it is not particulary tight) in order for the cotterpin to go through both nut and fulcrum pin. I could not go the other way and tighten it some more past 40. I did use Locktite.

4. Something I keep wondering about - I think I read someplace that the proper technique is to bend over just one of the legs of the cotterpin. Doesn't make much sense to me, unless you intend maybe to re-use the pin but that is a total no-no these days.

Am I good to go?

HEY!! I used crocus cloth on the fulcrum pin to clean it up - do I get exra credit??

Cheers,

Adrian

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>