luke44

Jedi Warrior

Offline

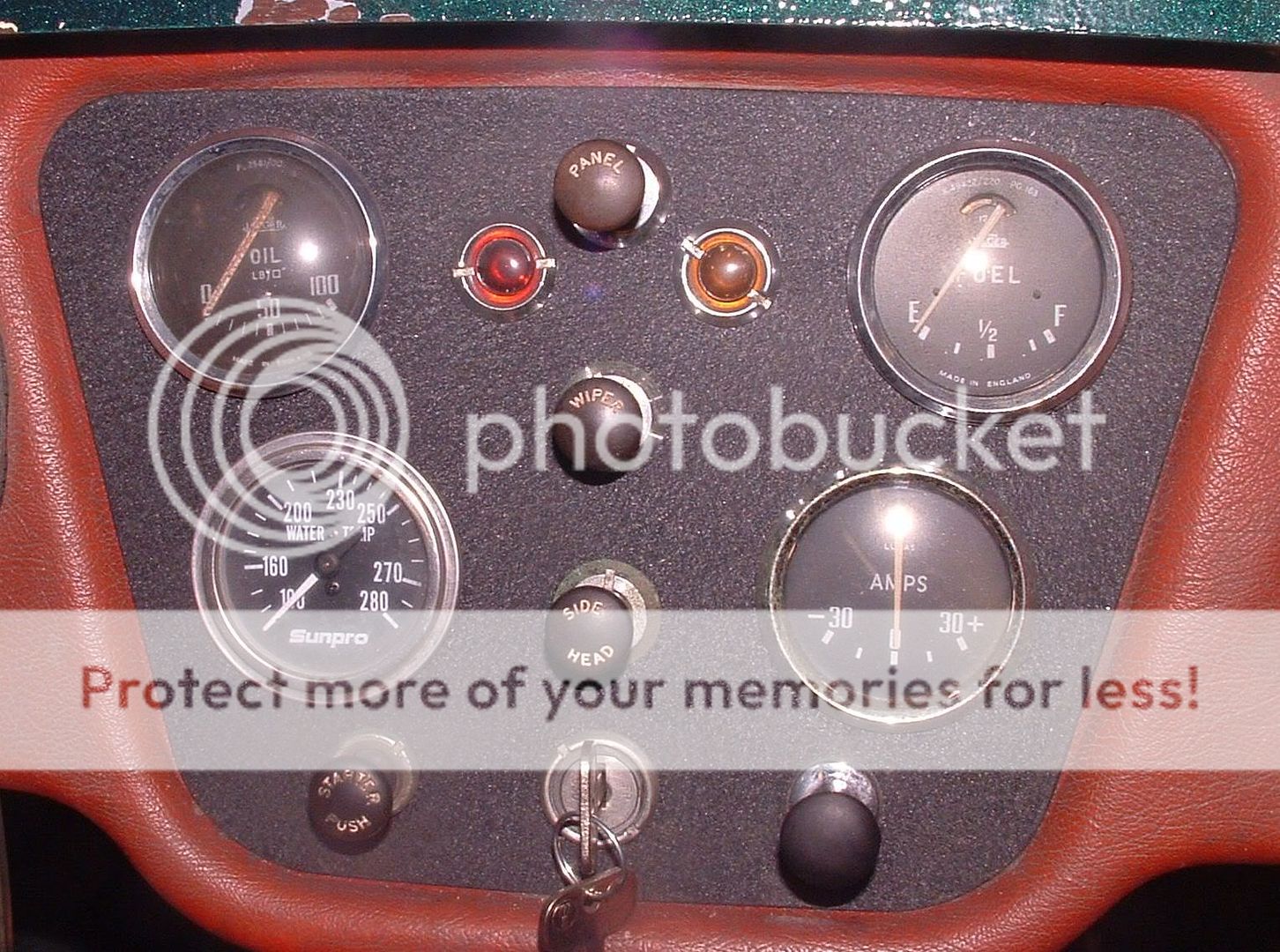

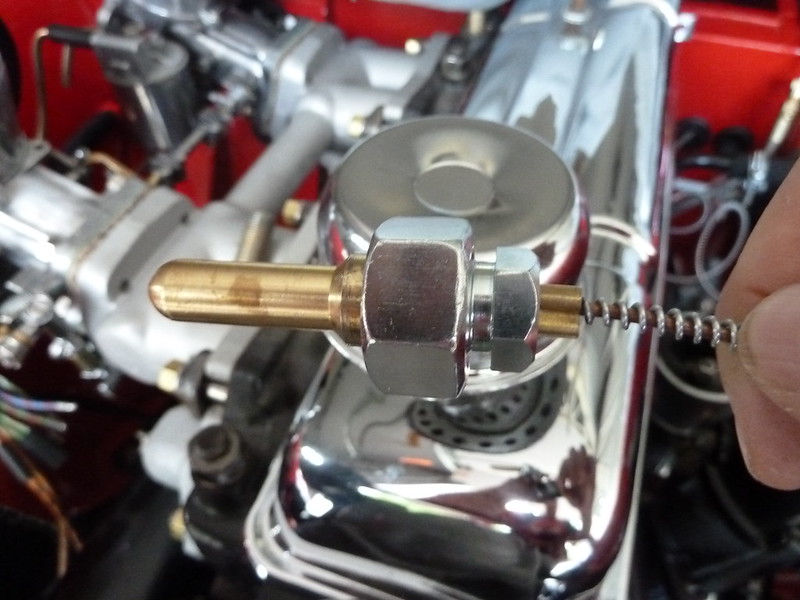

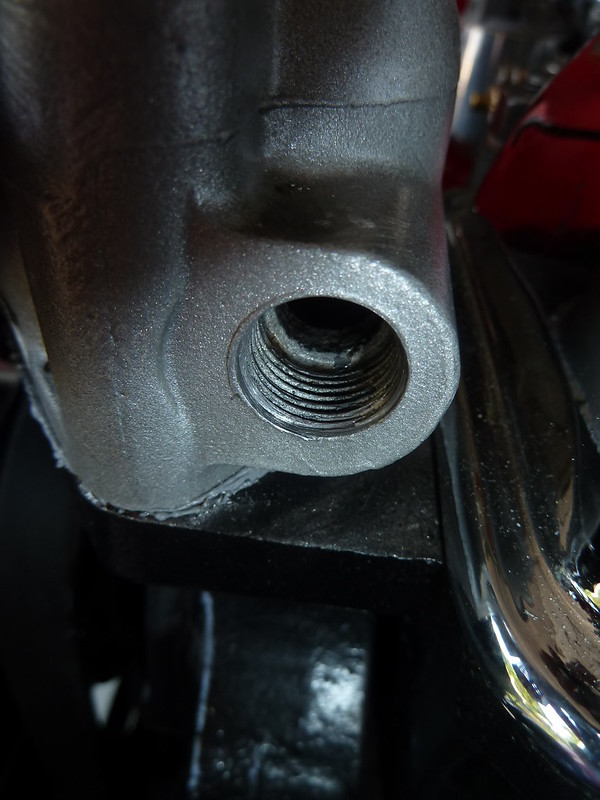

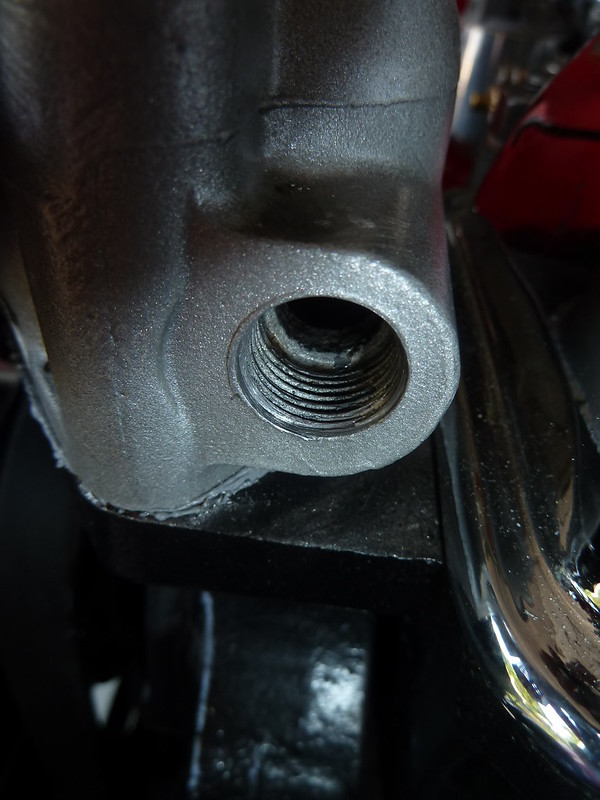

Has anyone run into a problem installing the sensor into the thermostat housing on the TR3? The threads just don't want to catch. Yet the threads are from a brand new/rebuilt gauge and seem fine. I’ve at least figured out it is 5/8 x 18 thread and not pipe thread, so, do I try a 5/8” x 18 bottoming tap which will cost me $26.00 to buy for a once in a lifetime use, or do I try a grade 8 bolt and may be cut a couple of slots in it with my die grinder and try to make a pseudo home made tap? Or a $49.00 new housing...Or, does anyone else have another other ideas? Frustrating. What should have been a 2 minute job to button it up has blown my whole afternoon :confuse: ... All comments welcome.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>