BTW, Russ, while you've got the head off, try spinning a new 1/2-20 nut down each of the head studs. If it binds about 2/3 of the way down, the threads on that stud are probably distorted and the stud should be replaced. Running a die down them to clean up the threads is not a good idea.

Also make sure the hardened flat washers under the head nuts are present and in good shape. People sometimes substitute common hardware store washers, which can crush under the load and cause the studs to lose tension. And even the original factory washers wear down after enough on/off cycles.

I like to install the head gasket smooth side down, as mentioned in the early editions of the owner's manual. But I'm not convinced it actually makes any difference; that information does not appear in the later manuals and the gasket was modified to allow installing it either way. Just seems to me that the folded edges of the gasket might be more secure against the larger surface of the head.

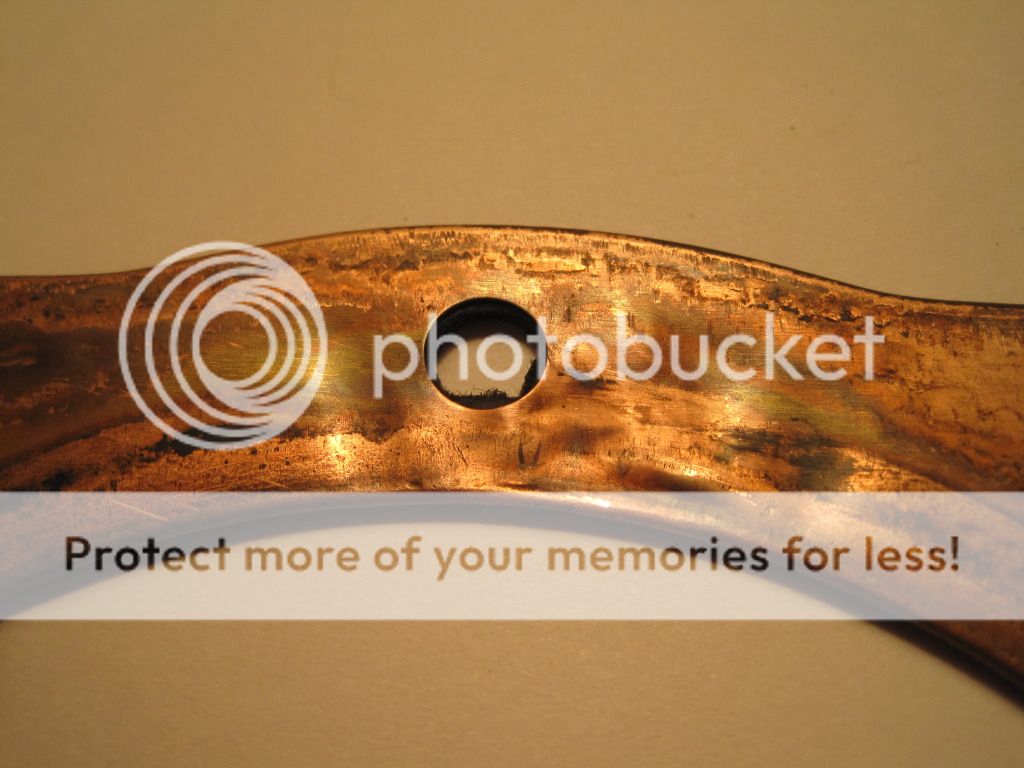

I hesitate to mention this, as it's strictly a kludge and perhaps not appropriate for you since all your liners stand up as they should. But on my TR3 engines where the liners don't stand up far enough, I've been tack soldering a ring of 26 AWG "half hard" bare copper wire around each cylinder, just outside of the folded edge of the head gasket.

I have not had a single head gasket problem since I've started doing this, even on the engine in my (now wrecked) TR3A that used to always start leaking within 3 months of a new gasket. I even reused one of the gaskets, and it still held the second time. YMMV

PS, don't forget to follow the tightening sequence in the manual, and tighten the nuts down in stages. I like to go to about 50-60 ftlb the first time, then about 85, then the final 100 ftlb.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>