Hello All,

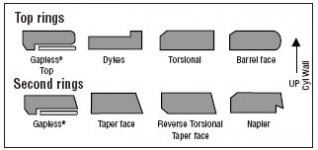

Ok so I am in the process of reassembling my tr3 engine with almost all new parts! With only 54K on the car I was astounded at the amount of wear i found! I have purchased the 87mm liner piston and ring set from one of the three big parts houses. Upon sitting down to check my ring gaps i found that at about 1 inch into the bore nearly all top rings measure a .018 gap and the middle rings measure .014 to .016. My Question, are those gaps acceptable? Secondly I have yet to figure out a way to get an accurate piston to liner clearance. how is this accomplished, i have tried with a feeler gauge set and the clearances appear to be through the roof when measuring from the top of the piston! please any help on the subjects would b greatly appreciated being as i would like for this engine to have a little compression and not piston slap like crazy!

Ok so I am in the process of reassembling my tr3 engine with almost all new parts! With only 54K on the car I was astounded at the amount of wear i found! I have purchased the 87mm liner piston and ring set from one of the three big parts houses. Upon sitting down to check my ring gaps i found that at about 1 inch into the bore nearly all top rings measure a .018 gap and the middle rings measure .014 to .016. My Question, are those gaps acceptable? Secondly I have yet to figure out a way to get an accurate piston to liner clearance. how is this accomplished, i have tried with a feeler gauge set and the clearances appear to be through the roof when measuring from the top of the piston! please any help on the subjects would b greatly appreciated being as i would like for this engine to have a little compression and not piston slap like crazy!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>