kstanley44

Member

Offline

Hi JP,

Looking good. We are at similar places right now. As John suggested I am swapping out the plexiglas lid for glass on my blasting cabinet. Hard to see!!

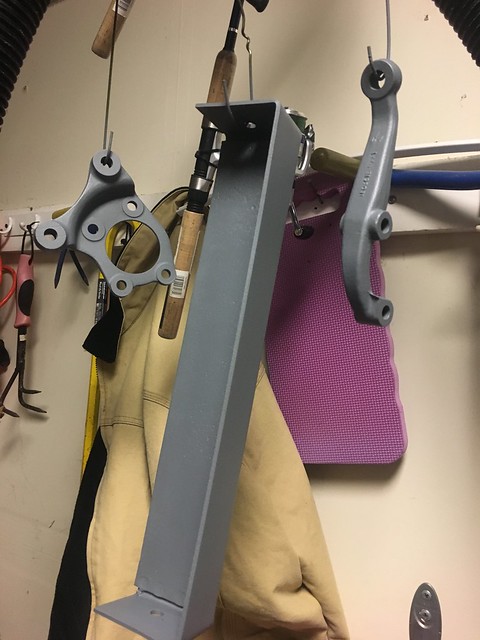

My bumper brackets from 62 TR3b also have the welded on nut.

What are you folks using for paint on the small suspension pieces? Using a spray gun or just using rattle cans?

Take care,

Looking good. We are at similar places right now. As John suggested I am swapping out the plexiglas lid for glass on my blasting cabinet. Hard to see!!

My bumper brackets from 62 TR3b also have the welded on nut.

What are you folks using for paint on the small suspension pieces? Using a spray gun or just using rattle cans?

Take care,

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>